This article was written to warn all property owners, managers, building engineers and service contractors:

There are potential risks of a major failure of your building (VPM or CP) axial fans.

Preface

Variable pitch in motion and controllable pitch axial fans became popular in the 1970's and 1980's.

The VPM and CP axial fans have remained popular up to 1990's, but with the VFD revolution the majority have been converted to a/c variable frequency drives.

There are still many VPM and CP axial fans (2017) that have not been VFD converted due to economics or based on the larger horsepower models when conversion is not economically beneficial.

A Brief History of VPM / CP Axial Fans

During the 1970's and 1980's many commercial buildings and hospitals were being built in major cities and towns throughout Canada and USA.

If you're old enough you'll remember the presumed energy crisis in the 1970's. Engineers and building owners were searching for more economical technology to move air through buildings with cost savings and pay back features. DC motors were tried on some fans (centrifugal) but found to be failure prone, high cost and too much maintenance. Large centrifugal fans take up more space and the mechanical inlet vanes or other mechanical variable volume devices can not produce high efficiencies or cost savings and the convenience that smaller VPM / CP axial fans could.

Variable blade pitch in motion technology came from the aircraft industry. Propeller driven aircraft / helicopters use variable pitch blade mechanisms to alter the propeller blades during lift off and flight.

Various fan manufacturing companies had developed axial fans with the VPM / CP features and this technology had become the best solution for the last three decades.

How Do VPM / CP Axial Fans Work?

The concept with VPM and CP axial fans works the same way as the propeller aircraft as mentioned earlier. The fan blade angles are modulated while the fan is running at the same speed as the motor

900RPM, 1200RPM and/or 1800RPM).

VPM fan blades are modulated by sending air pressure signals to a pneumatic pilot positioner onward through a rotary union at the nose cone that inflates a rubber diaphragm in the center of the VPM mechanism causing it to move back and forth.

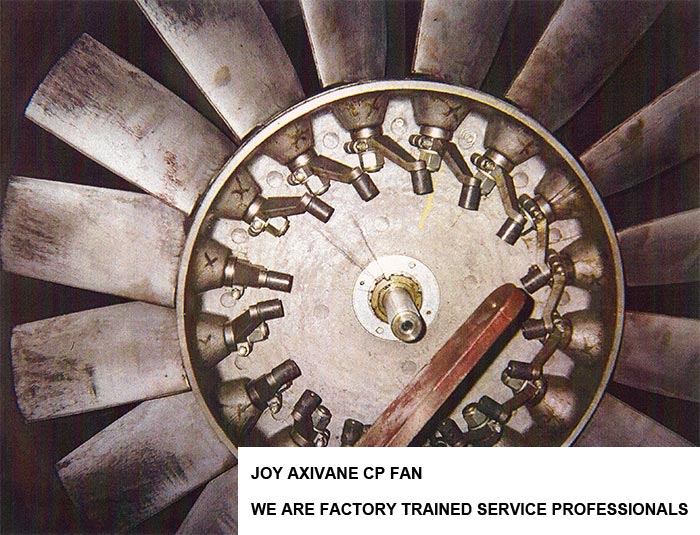

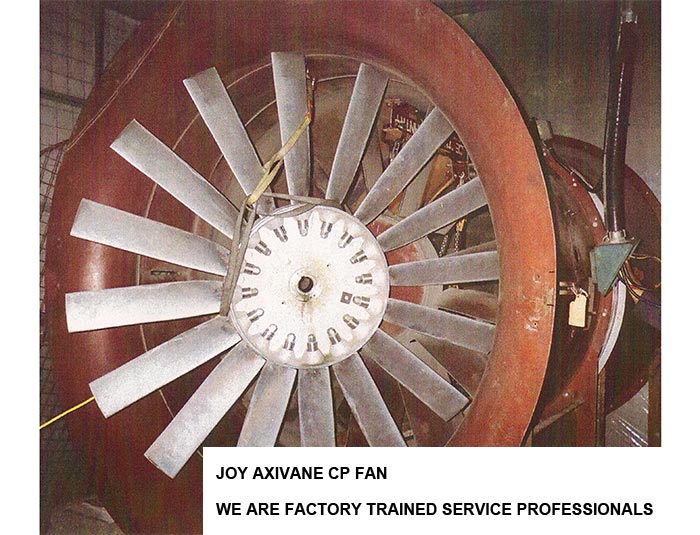

The CP fan blades are modulated by an external pneumatic actuator and lever arm across the front of the fan. The CP mechanism is pulled back and forth with a clevis assembly connected to a center thrust bearing assembly in the middle of the fan.

Both VPM and CP axial fans have a similar blade altering assembly that can be referred to as a spider section, diaphragm chamber, thrust bearing assembly, torque arm clamps and rollers. The VPM and CP mechanisms slide back and forth on a central hub slide way or an extended motor shaft.

As mentioned above both VPM and CP axial fan blade modulation is controlled by an air pressure signals. As air pressure signals are sent to the positioners the fan blades increase or decrease based on system requirements. Direct Digital Control (DDC) can also be used to eliminate the need for a positioner on VPM models. Lower blade angles or less air volume demands in buildings would reduce the motor horsepower consumption and save energy costs.

Main Manufacturers of VPM / CP Axial Fans

Five of the most popular models of VPM/CP axial fans in Canada and USA are Woods VPM Varofoil, Joy CP Axivane, Flakt VPM Axico, Chicago Blower VPM/CP Vaneaxial, and Sheldons VPM Axico. Either VPM or CP axial fans do the job so one can presume that cost and delivery is always the bottom line on most projects.

VIBES Corp's Background with VPM/CP Axial Fans

This writer had the position with Sheldons Engineering, Cambridge, Ont. as field service engineer based out of the Calgary, AB. office. With extensive factory and on site training I was sent to job sites throughout Western Canada to deal with commercial and industrial fan, motor and HVAC system issues.

Responsibilities included customer training, fan start ups, testing and warranty services at power, gas and chemical plants, oil refineries, industrial plants, mines, pulp, paper and lumber mills, commercial buildings, hospitals, government buildings, etc. from Winnipeg to Victoria and numerous small towns in western Canada. Problems that had to be solved included vibration, noise, balance, alignment, aerodynamic and mechanical issues on HVAC systems, fans, and motors from 1HP to 4000 HP. On larger projects our duties included supervision of various trades during shutdowns and retrofits.

Many VPM and CP Fans Have Failed Over the Last 30 Years for Various Reasons

Failures were caused due to various problems such as: lack of proper maintenance, poor design features, weakness in some parts, rushed factory assembly, lack of system control, wind milling and aerodynamic "Stall". Stall is the term used when the system pressure exceeds the maximum peak on the fan curve. Fan stall is a very unstable operating condition and the excessive aerodynamic turbulence can cause fan blade fatigue stress cracks and wear on VPM / CP parts if not resolved.

Higher resistance to flow at the inlet or outlet of the fan can cause the axial fan to stall. Stall will occur in a small window of operating conditions and can be identified with a sudden major increase in noise and vibration levels with an immediate reduction in performance. Axial fan stall can occur due to the following problems:

- Closed or poor damper control in the system - while the fan blades are at mid to max pitch angles

- Dirty coils or plugged filters

- Poor calibration, or defects at the positioner / Actuator

- Fan blades are seized at maximum blade angle when the system demand is minimum blade angle

Note: Stall detection / prevention devices have been on the market for many years but are not installed on all fans as they are an expensive optional assembly.

Example #1 Stall: Two 30 HP VPM axial fans in the same mechanical room running in a parallel system were found in stall (Very Noisy) on a job site. The stall problem has been present for a few years as the building operator reported there had been noise on these fans for a long time.

Filters and coils were found clean and dampers were working properly. The motor loads were measured at 31 amps each and both of the fans were in stall. By reducing the air signal to the fan VPM section it was found that while at 29amps both fans were out of stall. The solution to eliminate stall on both these fans was to slightly reduce the maximum pitch angle travel on the mechanical stop rods located within the fan center so that they never exceed 29 amps. The stall problem has never returned.

The issue on the above two fans is they were operating beyond the fan / system curve.

Example #2 Stall: A 75 HP VPM axial fan had been operating in stall for many years when blades were at maximum pitch angle. The problem here again was higher system resistance. Another issue was the fan was installed in a very small plenum with the inlet about .5m from the eliminator/coils. During a repair visit the eliminator blades were found broken, loose and a few were missing. This was causing the loose eliminator blades to rattle. One of the eliminator blades that had been removed due to defects was used to stop the rattling of the others by installing it in the horizontal position across the other remaining blades with sheet metal screws. When the fan was turned on and then modulated stall occurred at mid (middle) pitch angles. This proved how sensitive axial VPM fans are to stall conditions.

The final and only solution to the above problem was to remove the 9 blade axial VPM fan and install a 16 blade fixed pitch axial fan with a VFD retrofit.

Example #3 Stall: In this test the VPM axial fan blades were set at maximum pitch. Then duct branch balance dampers were closed one after the other from the nearest to the farthest from the fan. After closing approximately three or four duct branch balance dampers the sound of the fan could be heard in stall three floors away. This test proved that if balance or fire dampers were closed by accident or broken linkages the VPM / CP axial fan could go into stall.

Enough about stall as there are many other issues that can cause serious problems with your building variable pitch in motion axial fans.

Example #4 Wind Milling: When axial fans are blowing into the same system wind milling will occur if there are no back draft dampers installed at fan outlet and/or backdraft dampers are present but stuck open. Axial fans have been found to explode (all blades disintegrated) away from the hub due to high speed wind milling. Wind milling occurs when one of the fans in a common system is off and the other fan/s is running. If no back draft dampers are installed and/or stuck open the high airflow from the other fans is re-circulated through the other fan that is off. Using a stroboscope on one wind milling fan the reverse speed was 450 RPM. Yet on another job site the reverse speed could not be measured due to access and dangerous location but it was calculated to be the same speed as the fan that was running.

Dangerous conditions occur when the fan that is wind milling is started. The sudden reverse start into the opposite or correct rotation can cause a failure of the blades and/or shear off the motor shaft.

Several VPM /CP axial fan failures have occurred for various reasons throughout Canada within the first two years of coming into the market (70's and 80's) and many more for years afterward. Extensive research was completed by independent engineering testing, failure analysis and metallurgical firms. Those tests and our own experiences lead to a thorough understanding about how and why these types of fans can self destruct.

During the last 30 years in Alberta and British Columbia, Canada, this writer has prevented potential failures on hundreds of VPM/CP axial fans at numerous locations based on maximum due diligence practices. VIBES-GUARD PdM PROGRAM® is a Vibes Corp registered trademark and was created to assure clients they're receiving the most experienced and comprehensive maintenance service based on the knowledge being shared within this article.

I also had several opportunities to check the latest improvements and upgrades (as of 2017) to a particular model of VPM axial fan impeller to stop the failures. The failures rates have decreased over the last 20 years but there are still many of that model of axial VPM fans in service today and to my knowledge no customer warnings have ever gone out to the industry explaining all the reasons for the history of failures. This article was first written and circulated in 2001 in Alberta and has been revised as of June 2017 to share experienced advice on how to check and maintain all types of VPM and CP axial fans.

VIBES Corp = Additional Training Courses and/or Factory Service Authorizations

Woods Fans, Westinghouse Electric, Joy Fans, Canadian Blower, Chicago Blower, New York Blower, Allied Blower, MarkHot, BAC, EVAPCO & MARLEY Cooling Tower Fans, and others.

To learn more, contact us.

Extreme Caution Is Highly Recommended! Do Not Attempt to Service These Fans Without Proper Training

There are many VPM and CP axial out there that could fail in the future if not checked and maintained properly. Also as fans get older maintenance should be done more often. In many buildings vibration switches or sensors have been installed on fans or motors to protect/alarm/shutdown or trend conditions.

Recommendations - Preventative Maintenance Tips

The following recommendations are meant to perhaps save a life, prevent serious injury and the cost and inconvenience of having to deal with major repairs or replacement of a failed VPM / CP axial fan.

#1 - Check the blades for excessive looseness. VPM fan blades usually have slightly more play than CP fan blades. If CP fan blades are very loose there is a problem!

No matter how the blades are held in position the blade shaft lock nuts on VPM / CP fans must be secured and tight. That is all blade lock nuts must be set so that a blade can never become free in the radial direction. The clearance between the tip of blades and the casing on all axial fans is usually very small so any looseness will cause rubbing. The use of Loctite 242 or 243 compounds on threads must be done. A record should be kept of when and who completed this most important first step.

NOTE: Even if lock nuts or lock washers of any kind are present coat the threads with Loctite 242/243 anyway.

During major servicing of impellers, if blade shafts were held with Nylock lock nuts, they should be replaced with new lock nuts or coat the threads prior to reinstall. Old Nylock lock nuts have been found to come loose from loss of compression strength if no Loctite was used.

In some cases it has been found that over tightening blade shaft lock nuts can cause stiffness in modulation. Therefor the use of Loctite saves the day as less nut torque will be required.

If this most important first step has never been done or verified in reports, check your fans ASAP!

#2 - Check, service and record all other internal conditions of each VPM / CP fan such as: Mechanical stop rods, motor shaft bolt torque, torque clamps, rollers, rubber diaphragm, reaction plate, actuator section, motor shaft castle lock nuts, lever arm ball joint/bushings, clevis assembly, thrust bearing lubrication, slide ways and/or shaft lubrication, blade shaft sleeves, nylon washers, etc.

Warning! Various VPM / CP axial fan parts could be worn or loose inside the center of the fan or hidden under the nose cone, but may not show immediate signs of increased vibration or noise at the time of periodic monitoring. Also read the fan manufactures maintenance manuals and follow that advice.

If this #2 most important step has never been done or recorded in written reports, check your VPM/CP axial fans ASAP!

#3a - All VPM axial fans have at least two or three mechanical stop rods that extend from the fan hub and/or the fan actuator section. The mechanical stop rods are factory set to prevent the fan from exceeding maximum blade angles that if exceeded would overload the motor and/or also limit the minimum pitch system performance angles.

#3b - All CP axial fan blade angles are set by torque on the blade lock nuts after the blades are set for maximum pitch angles at the hub. Motor overload (maximum blade angle) is controlled by the limit stop at the end of the slot slide way where the large steel lever arm slides back and forth during modulation.

#3c - Important Note! One type of VPM axial fan that was installed in the 70's and 80's was found with the two hub stop rods very loose on many job sites. The problem is that the two stop rods are screwed into the hub wall to a depth of about 25mm. No method of extra stop rod locking was designed for this model. The VPM section slides back and forth along the two stop rods through diaphragm cover oil lite bushings that also wear over time. The two steel stop rods were being pulled out of the aluminum hub holes and/or loosening during maximum angle conditions. If this condition is excessive the blade angles will increase beyond design maximum and cause the motor to trip off and/or higher vibrations/noise will appear.

One solution to the above problem is to install longer stop rods that protrude about ¾" beyond the back of the hub wall. Insure the rods also have a longer threaded section so that lock washers and nuts can be installed on both sides of the hub wall. Again also use Loctite 242/243 on all threads.

Note: A small amount of Loctite 242/243 on threads is all you need!

You'll need to undue those parts again someday.

3d (continued from the same VPM model in 3c) - Another major problem on this type of VPM axial fan was the blade shafts were coming loose from the hub allowing rubbing at the blade tips. This condition would be heard in the mechanical room or a few floors down as machine gun firing. These models of VPM fans have been known to explode from prolonged periods (a few minutes) of blades rubbing the casing.

Solution is to make sure all shaft blades are tight to the hub and then drill through the hub wall and all the blade shafts to install dowel pins. This work would be more properly done and most convenient at a machine shop.

3e - On another type of VPM axial fan (70's 80's) the three mechanical stop rods / nuts were causing excessive burring at the actuator. That condition was also causing higher motor amperage and vibration.

The actuator section had to be removed from sites. The machine shop procedure would involve removing the burrs, machine a larger flat section and install larger diameter maximum stop nuts with flat face on the actuator side. The larger maximum stop nuts were designed to allow for a set screw that is tightened to the rod at the design blade angle.

If these 3a, 3b, 3c, 3d, 3e most important steps have never been done or recorded in written reports, check your VPM/CP axial fans ASAP!

#4 - Check for a loose fit between the fan hub and motor shaft. If this condition exists it is usually identified with an increase in vibrations and erratic mechanical noises (clunking) on coast down. Try to pry one fan blade at six o'clock with a thin flat bar or large screw driver to detect excessive vertical play.

Tolerances for acceptable clearances are usually +.001" fan hub or -.001" motor shaft. Note +/- .003" clearances is too much. Typically the best fit is when you have to use a puller or small hydraulic pump to get the fan off the motor shaft.

If you find excessive looseness between the motor shaft and fan hub bore it is usually requires machine shop repairs.

If #4 most important step has never been done or recorded in written reports, check your VPM/CP axial fans ASAP!

#5 - Check all blades closely for any defects, chips, dents, hair line cracks versus casting imperfections.

Record all blade conditions by numbering each blade. If uncertain about a significant defect call a metallurgical engineer to inspect and advise. Take digital photos of the fan blades and other parts.

Note: VPM/CP axial fans rarely fail due to metallurgical defects at the manufacturing level due to extensive quality control and testing. This is not to swear that it has never happened but it is very rare.

#7 - CP axial fans require more lubrication due to the large double ball thrust bearing in the center of the fan. The steel lever arm ball joint (clevis connection) and either end bushings also require more regular lubrication.

#8 - Vibration spectrum analysis, vibration meter measurements and using an electronic stethoscope for listening to bearings is important to trend the condition of VPM/CP axial fans and any machinery.

Vibration analysis, monitoring and trending the data is very economical compared to the cost of repairs or replacements due to sudden failures (even in 2017). Major motor bearings have failed suddenly and can cause extensive fan damages.

Other articles relating to Basic / Advanced Understanding of Machinery Vibration titled "Learn About Vibration" Vol. 1 (Basic) and also "Learn About Vibration" Vol. 2 (Advanced).

Important Note!

Due to the variety of vibration instruments and the experience level of the person that does the interpretation of the data don't rely on just the recorded vibration data to assess the condition of your VPM/CP fans and/or any type of machinery.

Major breakdowns and many potential dangerous defects have been found on all VPM / CP axial fans with no immediate increase in vibration or noise levels. Make sure to visually inspect and record issues by necessary disassembly on a once or twice yearly schedule.

Conclusion

Thorough mechanical inspections must be included during VPM / CP axial fan health monitoring visits.

The future of most VPM / CP axial fans is to lock all blades at maximum angle and add a VFD (variable Speed Drive). VFD technology has been refined, low costs, hydro company rebates the trend to convert is logical.

If deciding to convert your VPM / CP axial fans to fixed blade and VFD for the motors also make sure the motors are converter duty rated windings. You should also be aware of shaft currents also known as electrically induced bearing damage (EIBD). Many fans, pumps, and other machines that have been converted to VFD motors have been found with bearing defects within a short time caused by VFD induced currents into the rotor shafts that eventually causes bearing damage due to electrical erosion (micro arcing) called fluting. An extensive article is available for free on this subject: "Learn About Shaft Currents / EIBD".

Images – Flatkwoods fans

Images – Joy fans

Images – replaced fans, restored fans, balanced fans, etc

Contact VIBES Corp for fan services or reverse engineering

Questions?

If you have any questions please email me.

Yours in Serious Service,

Garrett Sandwell, MET, CVA, ASNT 3

CEO

Vibration & Electro-Mechanical Analysis, VIBES-GUARD PDM Program® Service Contracts, On Site - Rotors Dynamic Balancing & Custom Repairs,

Couplings, Pulleys & Drive Shafts Laser Alignment, Rogowski Coil (VFD) Electrical Discharge Tests & Reports.

Sales: WEG Electric Motors, Metalon Synthetic Grease, Cool Blue (Inductive Absorbers), Easy Laser, Wilcoxon / Endaq Vibration & Temperature Monitoring & Protection Products, (Misc) Isolation Springs, Drive Parts & Bearings, Machining, Fabrications, Sheet Metal Projects & Environmental Coatings. Learn About = Free Articles.

|