|

This is an article regarding vibration analysis, monitoring theory, application and the benefits it offers to facilities and power plant engineers, operators, managers, and maintenance technicians.

Common terminology used for machinery vibration

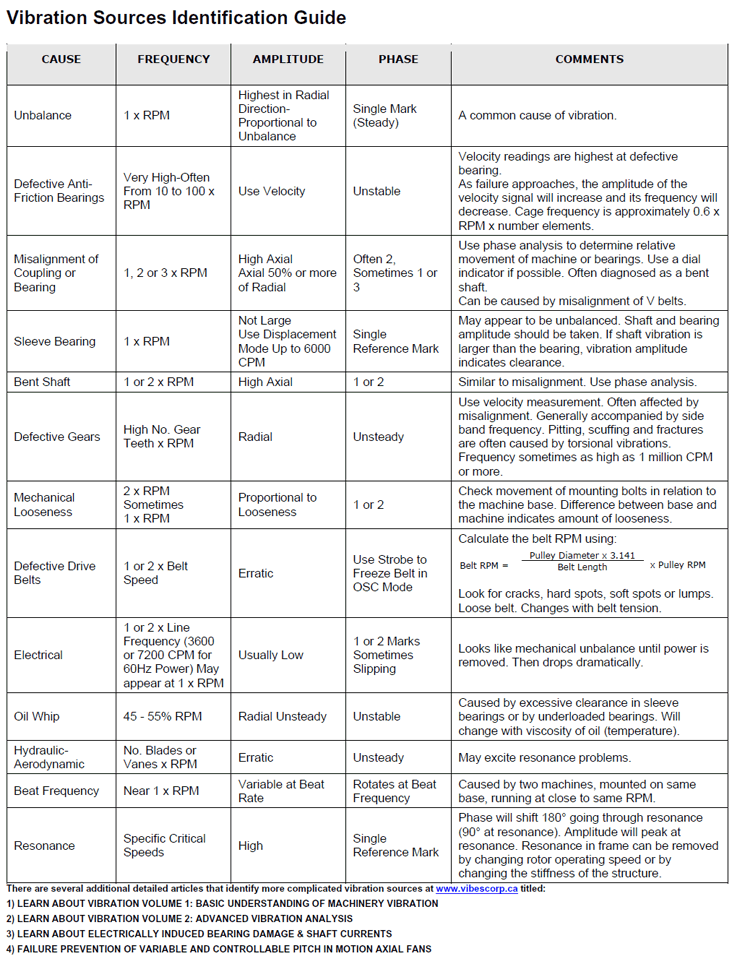

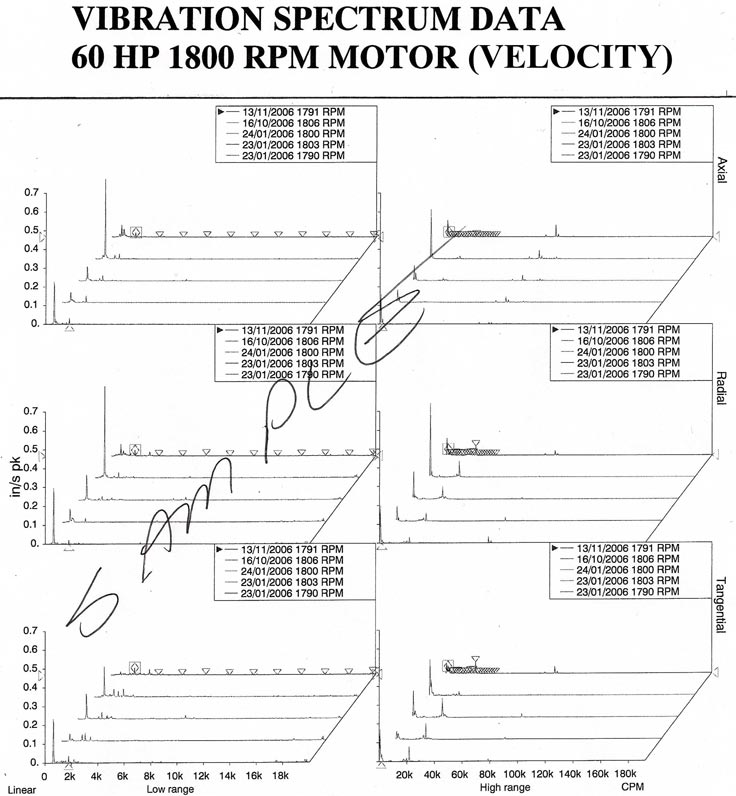

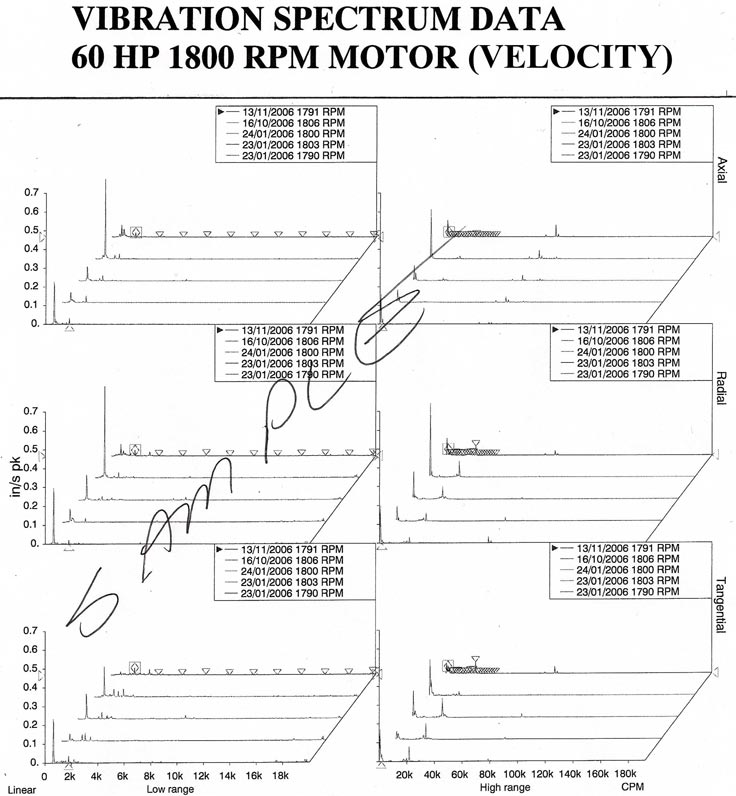

VELOCITY = Velocity of vibration is measured in peak units such as inches per second (ips) or millimetres per second (mm/s). Another way of looking at velocity is distance per time or how much is the machine moving every second in three important directions at all main bearing points (AXIAL, VERTICAL, HORIZONTAL). Velocity measurements and monitoring of vibration is the most common unit to identify various problems or acceptability such as: unbalance, misalignment, looseness (machinery structural, foundations, or bearings), harmonics, and many other issues in the machinery frequency range and many multiples of actual speed.

Velocity measurements (if using a single axis sensor/probe and hand-held meter) are recorded in three directions: axial, horizontal and vertical at all main bearing blocks or motor frame end bells. See drawings.

The convenient thing about vibration velocity is that it is not related to speed. Advanced computers with tri-axial sensors can measure in all three planes from one location.

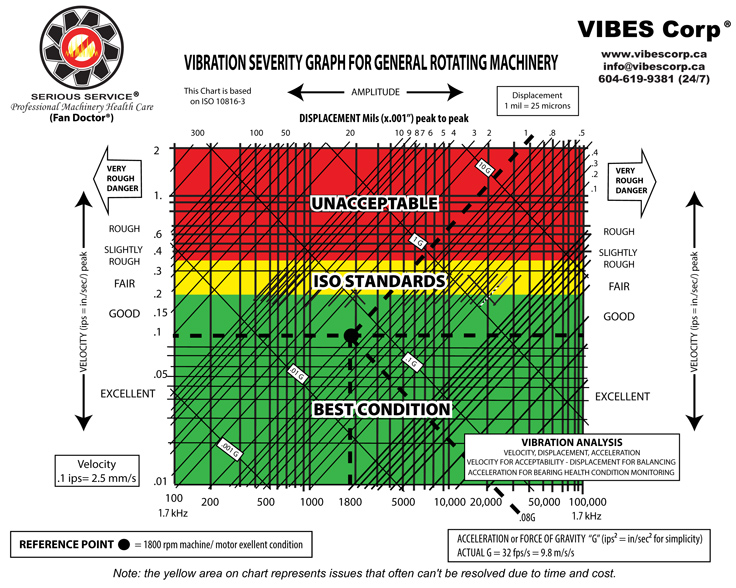

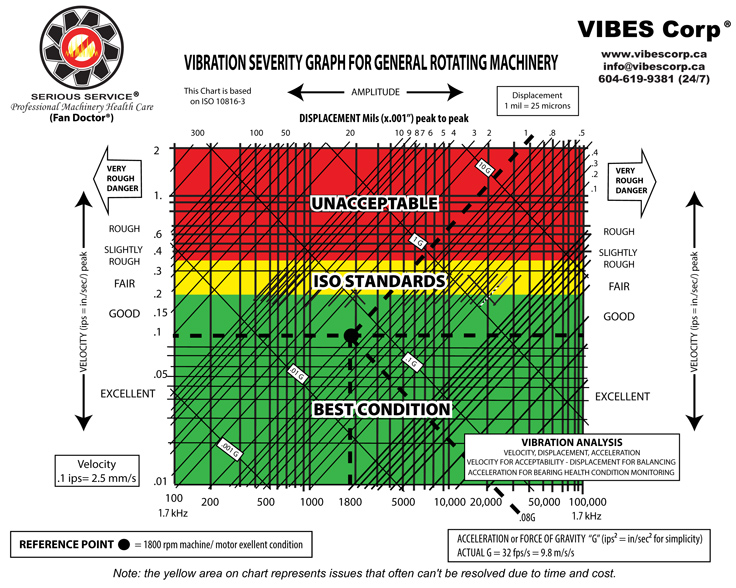

Overall or Broadband Vibration Severity using Velocity is applicable to all types of general rotating equipment (ISO/ANSI) operating at full load or speed condition. (Exceptions = Diesel Engines & Rock Crushers.)

ULTRA LEVELS = .05 ips / 1.3 mm/s or less at any speed. No action required.

EXCELLENT LEVELS = .1 ips / 2.5 mm/s or less at any speed. No action required.

GOOD LEVELS = .2 ips / 5.0 mm/s or less at any speed. No action required.

FAIR LEVELS = .3 ips / 7.5 mm/s or less at any speed. No action required, unless manufacturer's specifications state otherwise, and/or there has been a history of problems on a specific machine (Numerous repairs). The velocity .3 ips / 7.5 mm/s is typically the maximum BORDERLINE tolerance level in any direction Radial, Tang ential or Axial. In many circumstances it may be too costly or not practical to try and reduce vibration velocity below .3 ips / 7.5 mm/s in all sensor directions due to a variety of issues with: Structural or Support Base Weaknesses, System Turbulence, Be lt Tension Sensitivities, Poor or Grounding Isolation, Poor/Wrong/Worn Drives, Difficult to Balance Down Further, Very Hot Applications, Warped Parts, etc.etc.

ROUGH LEVELS = .4 ips / 10 mm/s or higher at any speed. (Take action soon.)

VERY ROUGH LEVELS = .6 ips / 15 mm/s or higher at any speed. (Take action now.)

DANGER LEVELS = .8 ips / 20 mm/s or higher at any speed. (Shutdown and Fix.)

The relationship of the above vibration velocity levels is found on the Vibration Severity Graph. It is important to understand that vibration can be smooth in one or more directions but very rough in another so record velocity in three directions at each bearing location and preferably within a few hours of start up.

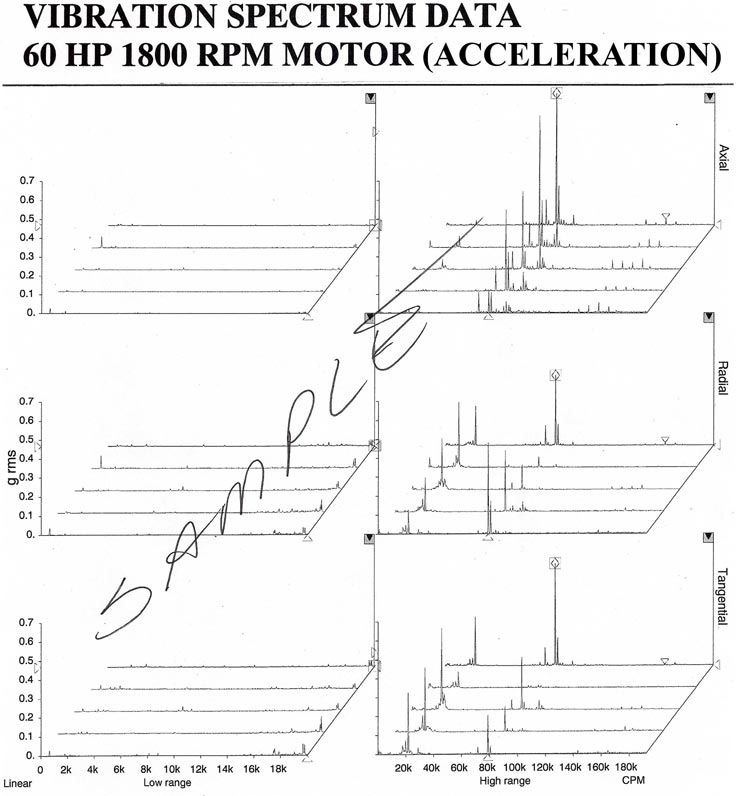

ACCELERATION = Acceleration data is very important for detection of faults with bearings, gear mesh or electrical issues . Acceleration is measured in units of G. Simplified = inches per second/second (ips/s) or millimetres per second/second (mm/s/s). Acceleration is very important bearing and gear fault data in the high frequency ranges. Acceleration is also a sudden change in velocity. Acceleration data are relevant in the rotational axis only. Some vibration meters have earphone output to allow the analyst to listen to the noise inside bearings w hile recording G. Listening to bearings using earphones such as an electronic stethoscope is very useful for defect identification. Ultra Sound Analysers can also be used for various tests.

Typical acceleration data related to all types of bearings in general rotating equipment. (Exceptions = Diesel Engines & Rock Crushers.)

EXCELLENT LEVELS = Usually .10 G or Less. No action required.

GOOD LEVELS = Usually .35 G or Less. No action required unless noisy.

FAIR LEVELS = Usually .50 G or Less. No action required unless noisy.

(If you have no records consider vibration spectrum analysis for all levels below.)

ROUGH LEVELS = Usually .75 G or More. Possible action required if noisy. Also check bearing temperatures.

VERY ROUGH LEVELS = Usually 1.0 G or More. Further analysis required. Also check bearing noise and temperatures.

DANGER LEVELS = Usually 1.5 G or More. Problem likely. Further analyze and check bearing noise and temperatures.

BREAKDOWN LEVELS = Usually 2.5 G or More. Shutdown and fix now! Dangerous!

Note: Actual G = 32ft/sec/sec. = 9.8 m/s/s. Vibration equipment converts these values.

As mentioned if unusual noise is present either audible or using electronic stethoscope the acceleration G levels are secondary. This means there could be an early warning of a bearing defect at .1 G level. Turn off machine and carefully listen to all bearings during coast down. If motor bearings are noisy, repeat this test with belts removed or coupling disconnected. Run motor to full speed then turn off and listen. While motor is locked off, and drive (belts or coupling is disconnected) check the rotor shaft for looseness by applying pressure in the vertical or axial directions to assess excessive play. Turn shaft by hand a few rotations and listen carefully for unusual noises in the bearings.

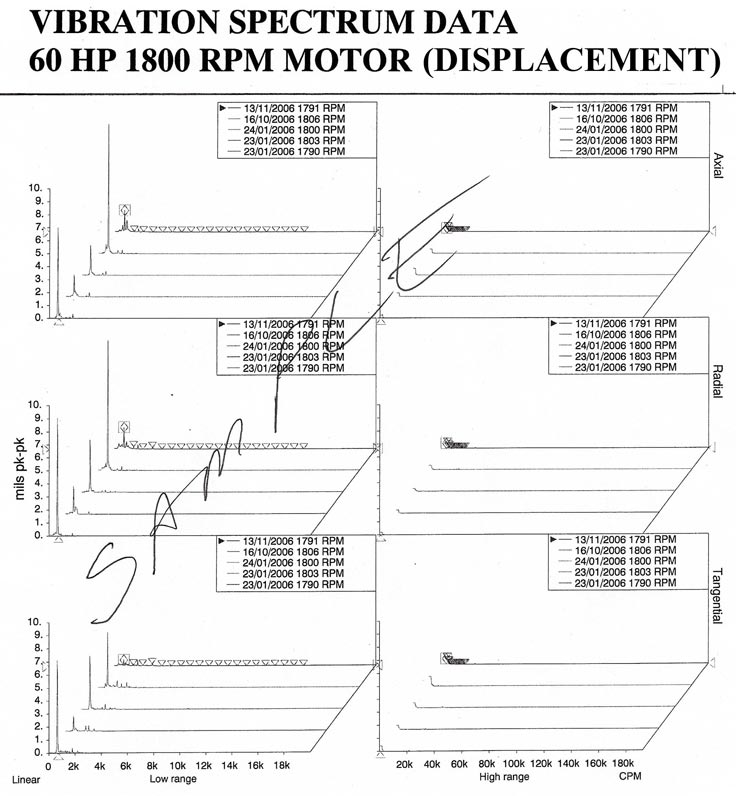

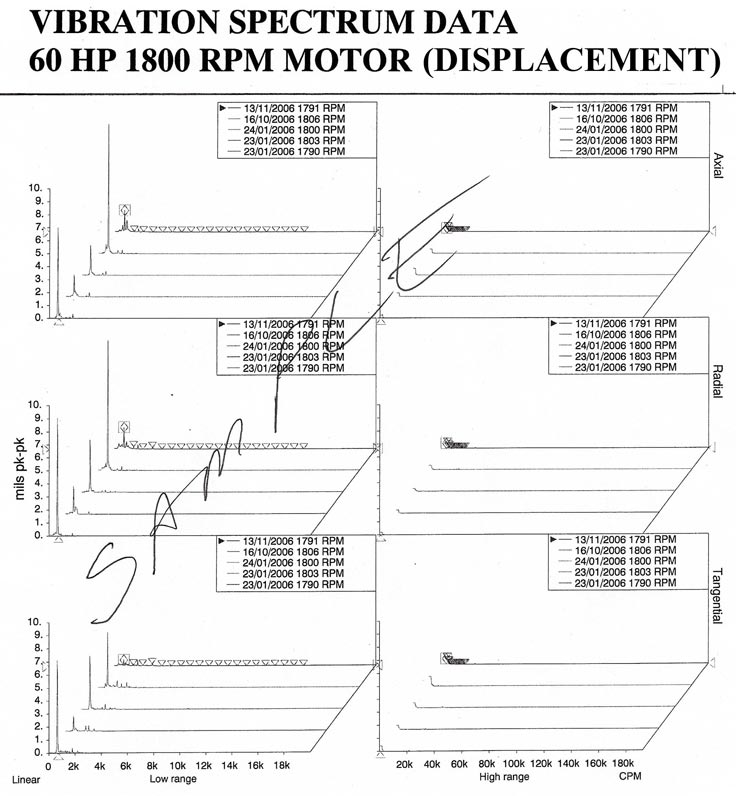

DISPLACEMENT = Displacement is measured in peak to peak units of mils (1 mil = .001”) or mm (1 mm = .0025”). Displacement measurements are recorded in the same three directions as velocity = axial, horizontal and vertical. Displacement is not used or recommended for recording or monitoring because severity or acceptability is speed dependent. Displacement is also used to identify problems in the lower frequency ranges. Displacement can be used for measuring reference values = walls, floors, beams, pads, frames = very slow moving or stationary objects. A tapered aluminum probe can be used to measure shaft axial motions. A Fish Tail™ Shaft Stick can be used to measure bends or misalignment with the machine running.

For example 1 mil at 1800 rpm = Excellent. But 1 mil at 30,000 rpm is Dangerous. Typically, rotor dynamic balancing tolerances are often specified in displacement (mils) because it has been an industry standard for 60 years or more. Other balance tolerances are gram/centimetres or tolerance grade tables. Typically, displacement is used in field and shop balancing procedures. For further information about balance tolerances/grades see: The practical application of ISO 1940/1.

FREQUENCY = Frequency is measured in units of cpm, Hz, Orders, i.e. 50 cpm – 750,000 cpm. Knowing the frequency of vibration peaks helps to pinpoint the potential sources. Frequency is used in advanced vibration analysis to identify all types of bearing fault frequencies, real time spectrums, and motor current signature analysis, etc.

PHASE = Phase is the angle of vibration issue. Phase is used to dynamic balance and identifies resonance (critical speed) problems. Phase is not used in everyday vibration measurements or monitoring. Phase of vibration is recorded using a stroboscope or infrared tachometer in conjunction with a vibration analyzer instrument. New technology and software is being used to add phase analysis to the final evaluation and diagnostics.

Most common causes for bearing deterioration or complete machinery breakdowns – based on 40 years of experience

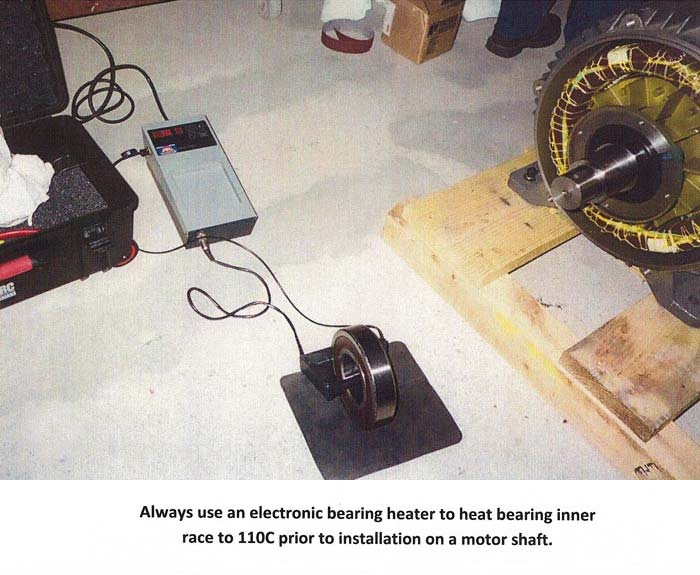

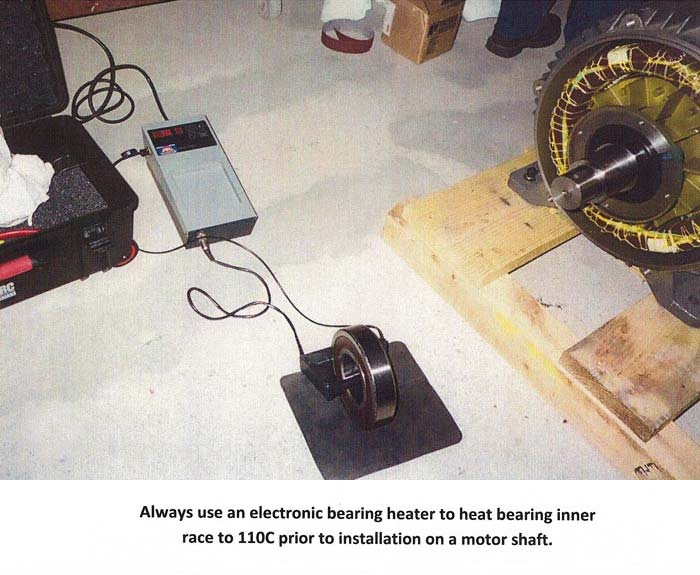

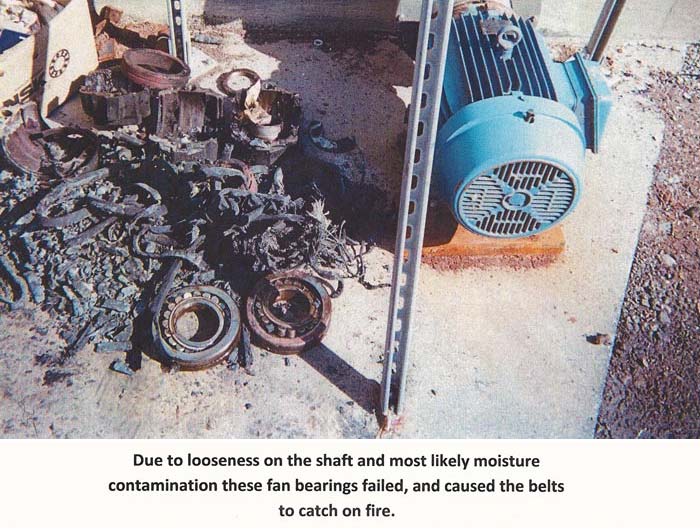

1) Improper installation. Bearings must be properly installed and aligned in three directions using machinist levels and other precision tools to maximize the lifespan and control vibrations. In electric motors the bell housing and shaft fit is critical. Bearings must be locked correctly to the shaft (concentric lock collars or locking adaptor nuts/rings). Shafts must also be within tolerances (not under or oversized) and no damage where the bearing is located. New bearings should never be installed into old/worn blocks. Always replace the entire kit. There is an industry saying = .0005” / .0125 mm under size can kill the bearing lifespan. In motor applications both bearing inner races must be heated to exactly 110C to expand and then shrink fit to shaft journal for perfect hold. Make sure to clean the motor shaft bearing journals or shoulders of any burrs with a fine file and use emery cloth to smooth surface of all roughness before installation of the heated bearing.

2) Misalignment of drives. Accurate alignment is very important to reduce vibration and prolong good condition of various parts. Check coupling manufacturer’s specifications and comply using double dial gauges or laser alignment. Remove belt guards during belt tensioning and check with level, straight edge or laser to insure pulleys are within tolerances at all times.

3) Belts too tight and/or too loose. Proper tension should be maintained at all times. Defective belts should be replaced as soon as possible. Retrofit to better drive system if necessary. Check for serious wear inside pulley grooves. Belt issues have been found to be a source of resonance.

4) Improper lubrication. Too much or not enough grease. Most good quality grease EP 1.5 – EP 2 on the market are acceptable but synthetics are the best. Lubrication charts are available for machines from the manufacturer. If mixing greases, lab test for compatibility. NOTE: On heavy duty machinery such as large HP hammermills or rock crushers you should contact the manufacturers for best grease to use.

5) Unbalance of the rotor. As this problem should be obvious it is usually resolved at start up. If vibration occurs suddenly on a machine, check for wear, debris build up, broken or cracked parts on the rotor. Unbalance in a variable speed machine usually shows up as a gradual increase in vibration as speed increases and highest at full speed. VIBES Corp specializes in rotating parts dynamic balancing on-site.

6) Vibration for a long time. Sometimes rough vibrations may be overlooked because the machine has always run that way i.e. harmonics, beats, resonance, transient vibration, flexing supports, aerodynamic turbulence , pump cavitation, misc. In axial fans check for "Stall" or on pumps check for cavitations. Axial fan "Stall" is due to increased resistance on the inlet or outlet and can be caused from damper problems, dirty filters or coils, fan blade modulation defects and other system issues. "Surge" is the same as "Stall" only it refers to centrifugal fans. During "Fan Surge" usually near or at full speed there may be an issue with dampers not opening or plugged filters on the inlet or plugged outlet screens. That resistance can cause "Surge" and you may notice extreme axial vibrations or erratic bouncing of the inertia pad.

7) Motor is operating beyond the full load amperage caused by over speed on the driven. Check the pulley ratios, use amp probe, tachometer or stroboscope to confirm driven speed is an issue.

8) Poor or no Isolation. Check springs for grounding, too much deflection, or wrong selection. Axial vibrations on fans often can be reduced with thrust springs. Pump or piping vibration transmissions can be reduced with expansion joints, flexible hose or spring hangers.

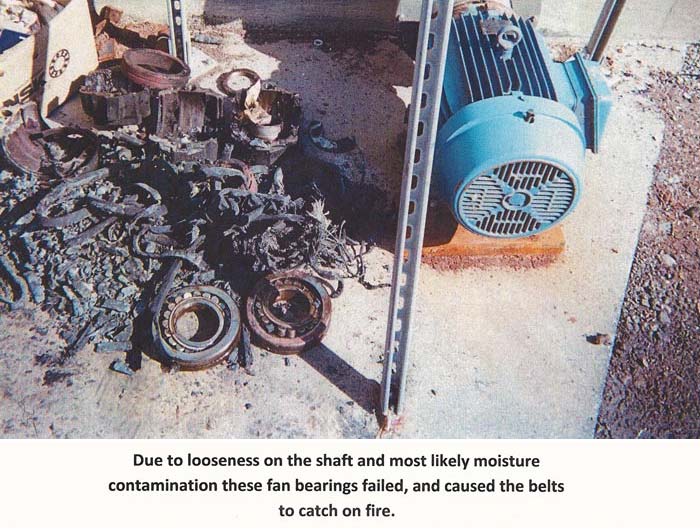

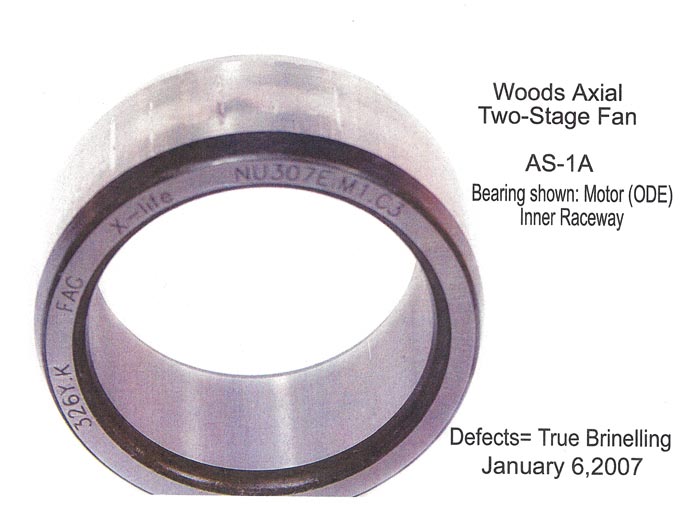

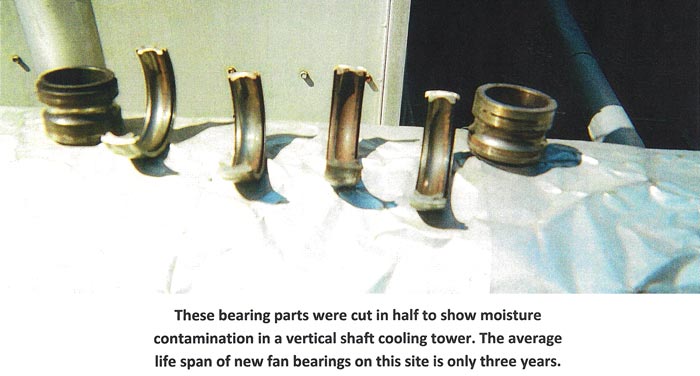

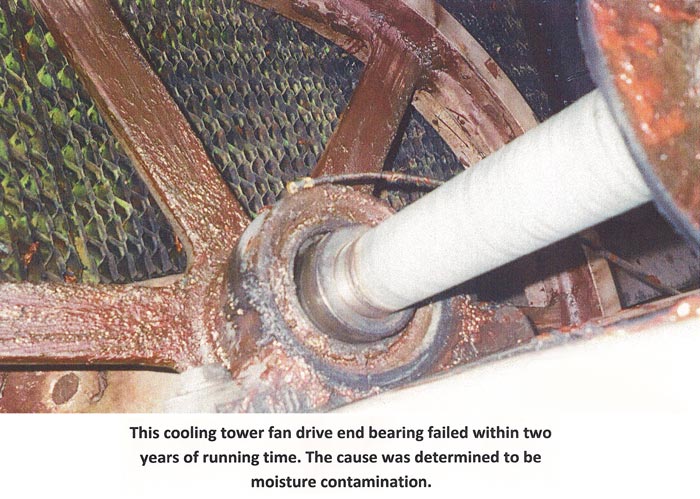

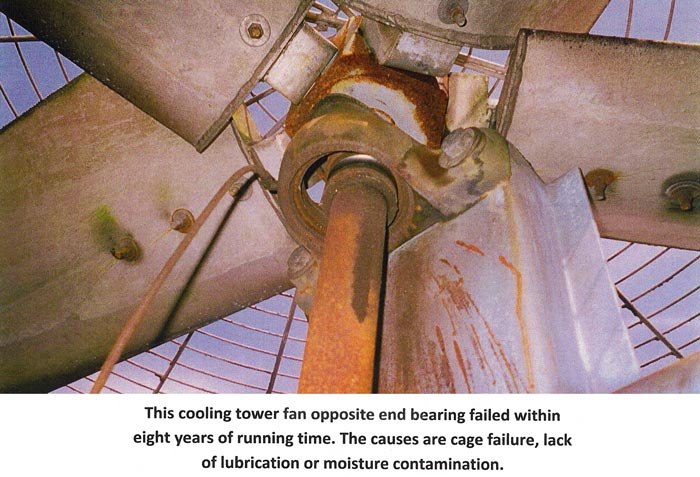

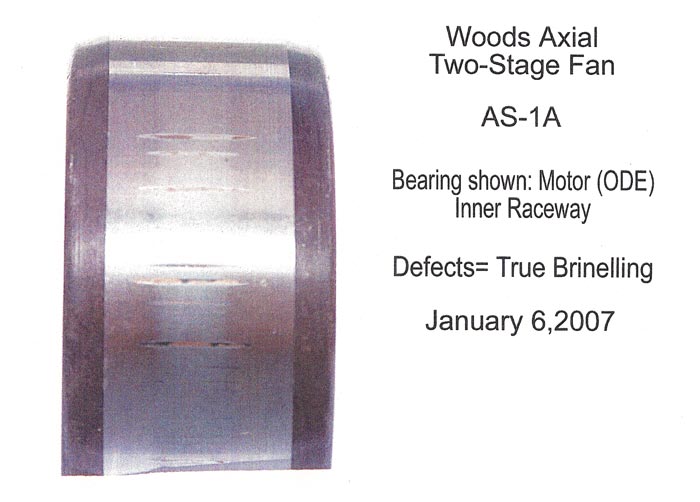

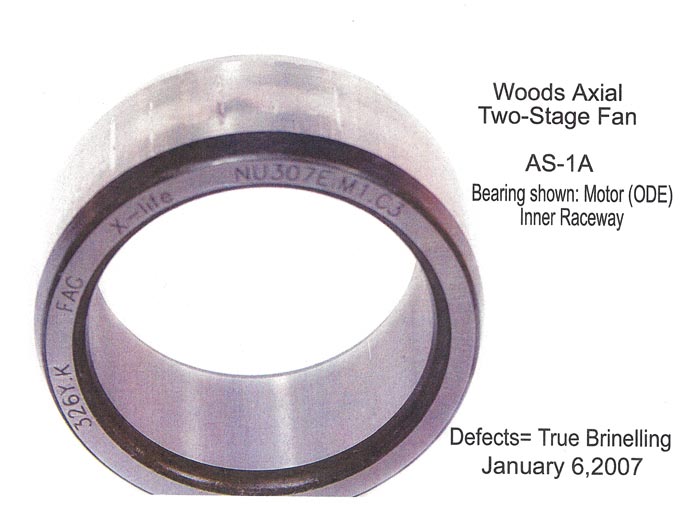

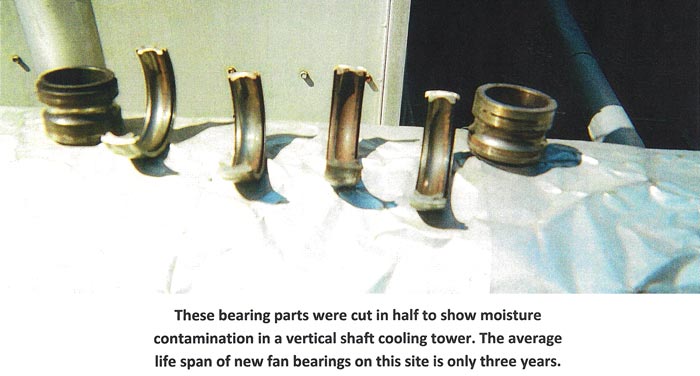

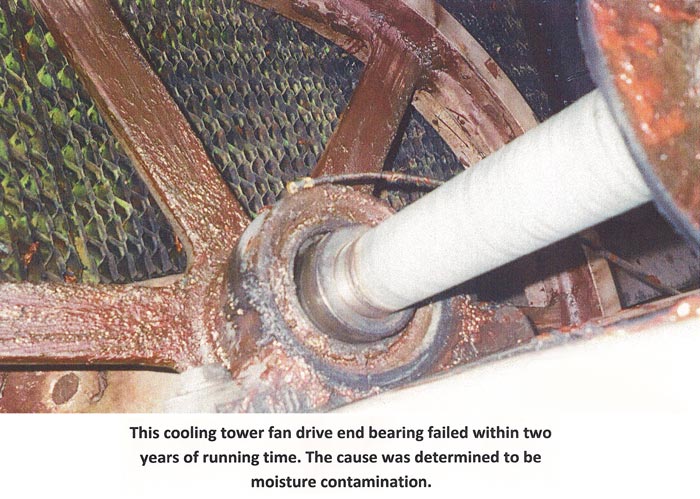

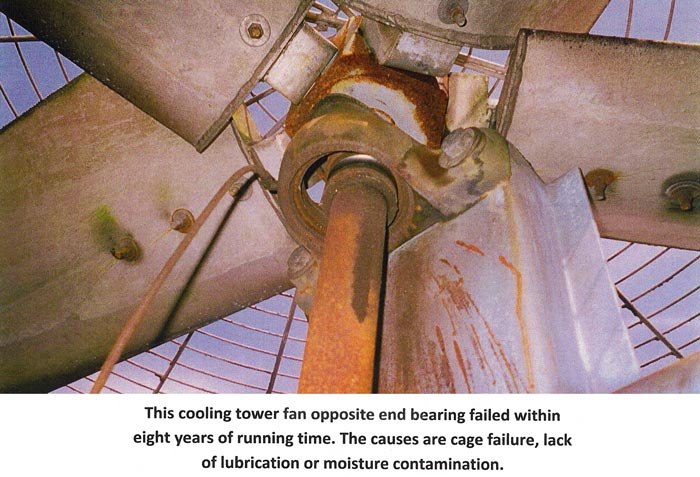

9) Bearing Contamination. Driven machinery bearings that are in harsh environments such as vertical shaft cooling towers, weather exposed, gaseous/moisture mix, or very dirty areas can become contaminated if not protected by special seals, cooling discs, or shaft assembly guards. Careful not to over grease motors. Motors should also be protected with silicone around bell faces and wire boxes if exposed to high moisture areas. Alternatively consider motors with sealed bearings.

10) Poor or wrong bearing selection. Sometimes when bearings are replaced the new bearings are not the same load rated as the original. Bearings should always be the same rating as the original and if consistently failing consider upgrading to higher dynamic load rated bearings. Large HP motors on belt drives should have roller bearings in the drive end and fixed ball bearing in the opposite end.

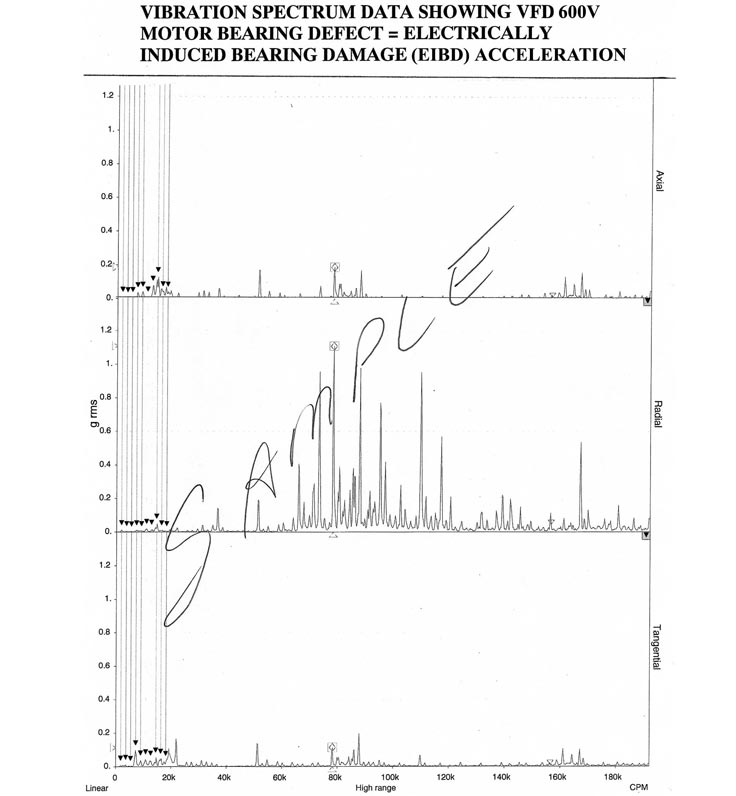

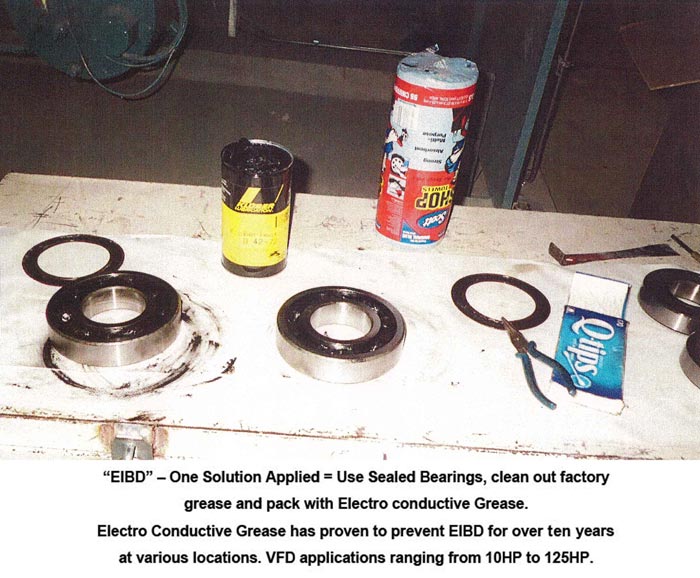

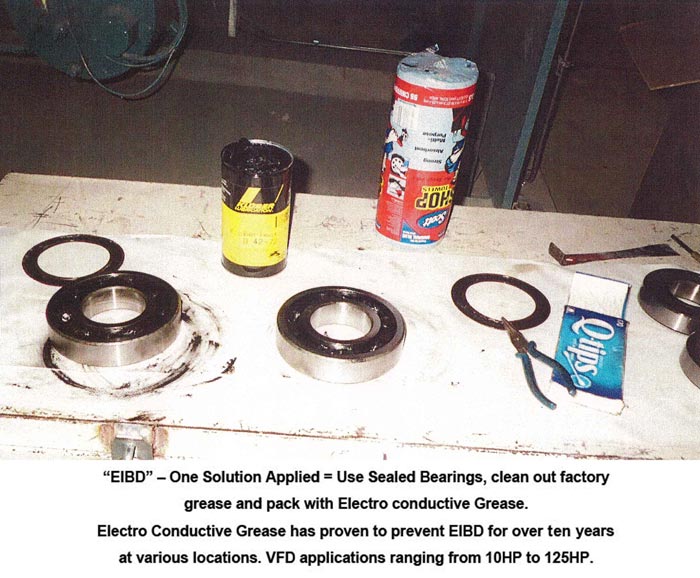

11) Electrically Induced Bearing Damage (EIBD) aka Shaft Currents, aka Electrical Discharge machining (EDM). Motors that are operating on 460V & 575V with VFD can often develop this problem which is caused by voltage build up in the rotor and the milliamps discharge (micro-arcing) through the bearings back to the stator. The result is LOUD bearing noises from pitting, glazing, fluting, micro-cracks and craters of the rolling elements and raceways along with burned/contaminated grease. There're various solutions to avoid or combat EIBD problems depending on the circumstances and budget such as:

- a) Sealed DE/ODE motor bearings packed with electroconductive grease (Kluber BE-44-152)

- b) Rotor grounding seal/ring (AEGIS / InproSeal)

- c) Sine wave filter (MIRUS INTERNATIONAL)

- d) Ceramic sleeves (SKF, FAG)

- e) Insulated bearings (SKF, FAG)

- f) Load side VFD electrical inductive absorbers (CoolBlue™)

- g) Magnetic Adjustable Speed Drives ASD (FLUXDRIVE)

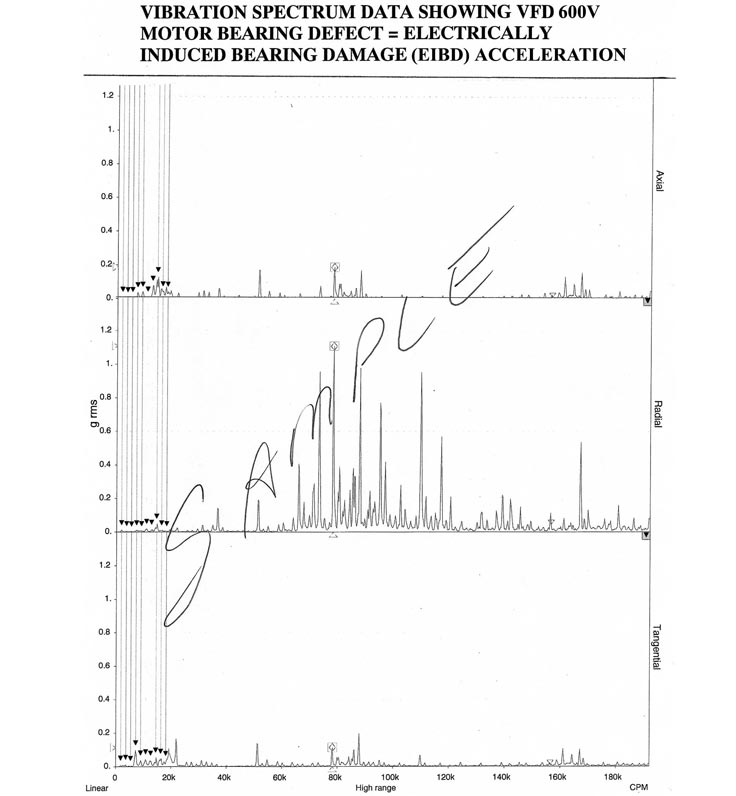

A more detailed article has been written and is available on our website: see Learn About Shaft Currents / EIBD. See vibration acceleration spectrum showing serious EIBD issue here.

12) Resonance is when the rotating speed and natural frequency are near or exactly the same. You'll notice a sudden and significant vibration increase at resonance. When converting a constant speed machine to variable frequency drive (VFD) or adjustable speed drive (ASD) you should run the machine up slowly to identify any resonance throughout the speed range. If you notice resonance you can try these four steps to control or eliminate it as follows:

- a) On VFD or ASD program the electronic signals to avoid that speed/frequency. Resonance can be present through a 1 Hz change in speed range usually above 45 Hz.

- b) Add parts to stiffen the machine. More tests required.

- c) Add mass to the machine. More tests required.

- d) Change the driven speed ratio by -10% -15% if it's a constant speed machine.

13) Soft Foot - Soft foot has been found to cause major increases in vibration usually on the motor. This problem should have been identified and corrected during alignment. To find soft foot problems try these two steps:

- a) Using (LIVE) display on your laser alignment instrument (soft foot) feature or on your vibration analyzer (Live) display loosen one motor foot at a time and obverse changes. Tighten each foot bolt/nut before undoing the next one and so on.

- b) Same test as above but using a dial gauge to record all four foot data (while machine is on/off).

Fact = Soft foot was found on a motor to change vibration overall from rough to good levels with a minor lift of only +.002".

Soft foot can also be the source of high vibration spike at electrical frequency or 7200 CPM but much lower peak at 1x RPM. The reason is stress on the stator frame when there is uneven contact at all four motor feet.

The above a) and b) tests will confirm if it's soft foot.

Important: Vibration data should be recorded at the same spot sensor direction and location when the machine or motor is operating at the same load/speed each time or the trending may become useless or confusing. If full speed is not possible record at the same lower speed each time.

Typically 80% speed or fan blade angles are satisfactory for vibration monitoring and trending (100% speed or maximum load condition is best for monitoring and evaluation).

Vibration spectrum analysis – advanced software and data collection

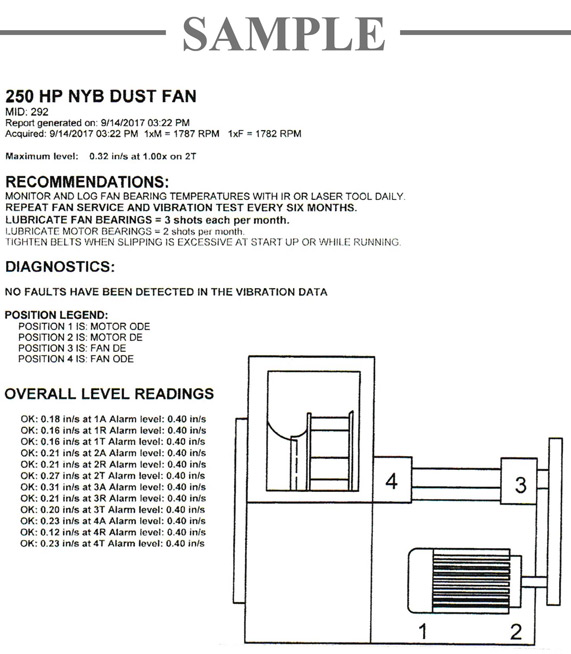

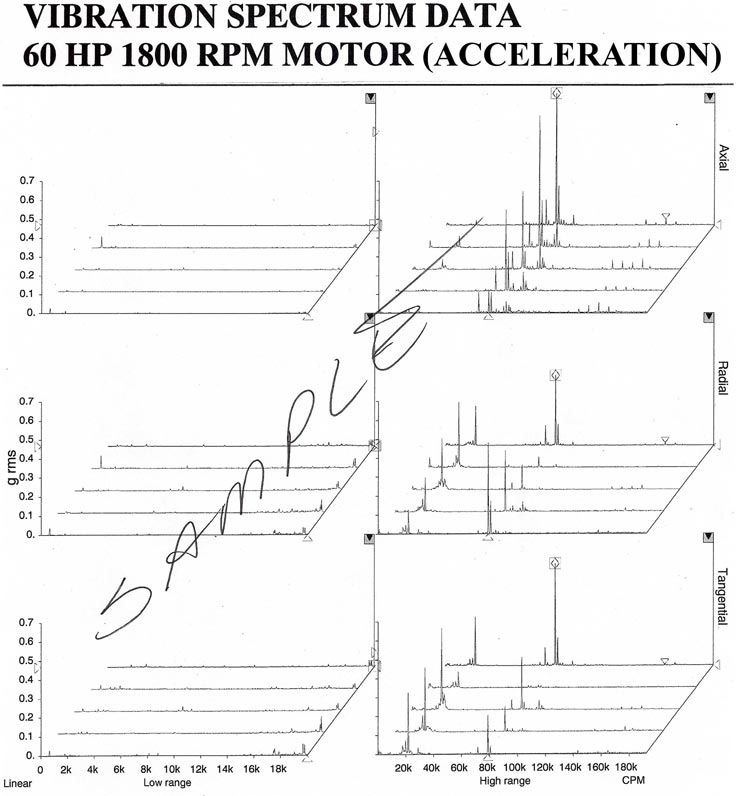

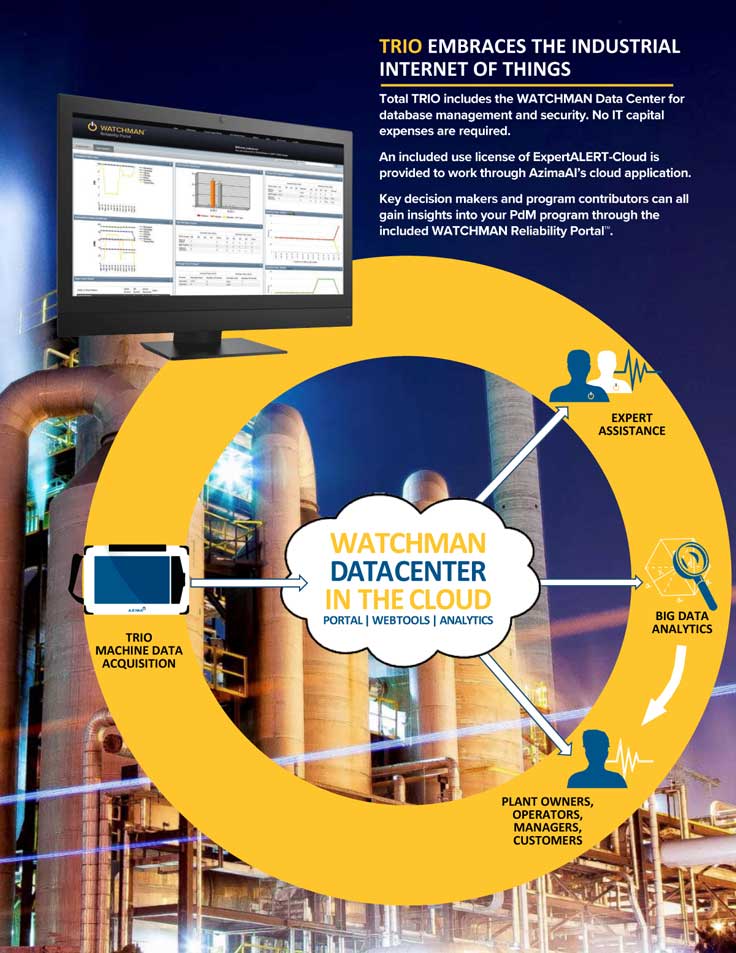

It is very important to have a record of the machine vibration baseline history after a few hours running time on the date of start up. Click here for examples of several motor vibration spectrum using velocity, displacement, acceleration versus frequency. The original motor peaks are shown for one location before with defects and after defects were resolved on several visits. The data is referred to as Waterfall Spectrum Plots. A software program such as Azima DLI ExpertAlert™ can identify many faults. After several sets of data (5 sets) are available the Waterfall reports become very accurate for trending, PM planning and failure prevention. In the machinery baseline vibration spectra we have everything we need to know about that equipment in the database history. As mentioned when several sets of data are recorded the ExpertAlert™ engineered software produces accurate detailed diagnostic reports that are rule based. The EA software screens for specific fault frequencies on 9500 bearings for all types of machines or engines and compares the recorded data to good data. See another more detailed article on our website: Learn About Vibration, Volume 2: Advanced Vibration Analysis. You can also contact Azima DLI for product information. Note: Vibration articles and training materials are constantly changing so search for updates at various sites.

Q&A

Q1) How often should I have vibration monitoring or analysis done on my machines?

A1) HVAC equipment should be checked once or twice per year. Industrial machinery should be checked more often. Some important machines are monitored 24/7. Example: gas plants, power plants, wind turbines, etc.

Q2) How much does vibration monitoring or analysis cost?

A2) VIBES Corp would be pleased to quote vibration analysis, PdM monitoring program, dynamic balancing and alignment projects at any time. Equipment can be (basic) monitored and inspected for as low as $250-$350 per machine or less. It always costs less based on volume per site. Complex machinery monitoring or analysis costs will be higher. Costs vary depending on Basic, Advanced, Inspection Requirements, Number of Machines at one location, Number of visits/year, and location of job sites. VIBES Corp will be pleased to assist with all your vibration, balancing and alignment requirements.

Q3) Should I consider mounting a permanent vibration switch or transmitter on my critical machines, engines or motors?

A3) Yes. As equipment gets older the chance of a sudden vibration-related breakdown increases. Vibration switches and transmitters are (4-20ma) low cost and gives you 24/7 protection, measuring, trending, alarm, trip settings, time delays and can operate via WIFI or installation of vibration transmitters from critical machines to control room panel meters up to 1000 ft away. Computer can be programmed to alarm if maximum pre-set limits are exceeded to alert you right away. Another lowest cost alternative is a simple motor shutdown switch such as a MURPHY vibration shock/shutdown switch. For specifications on Murphy, Spectrum and Wilcoxon vibration products go to our home page.

Don’t wait for a machine or motor to fail!

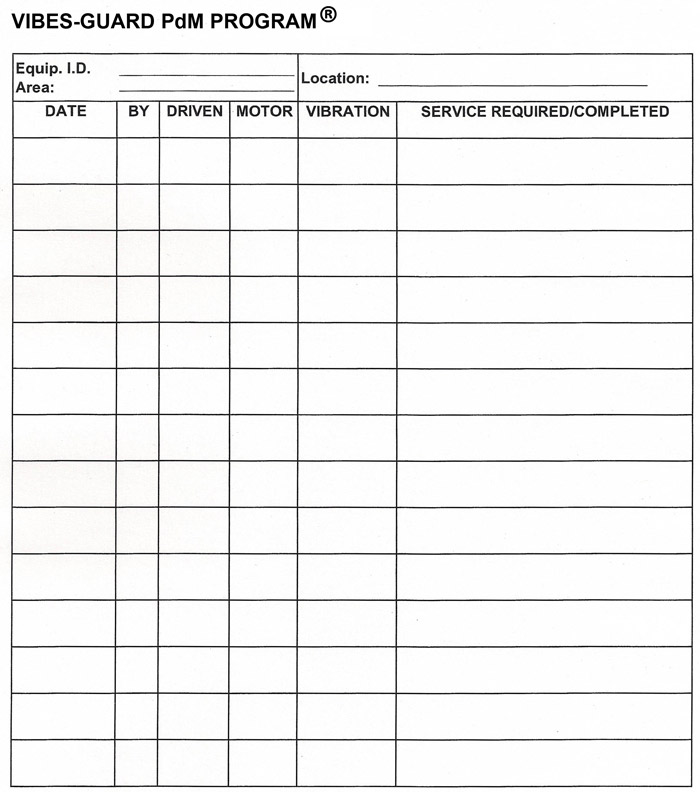

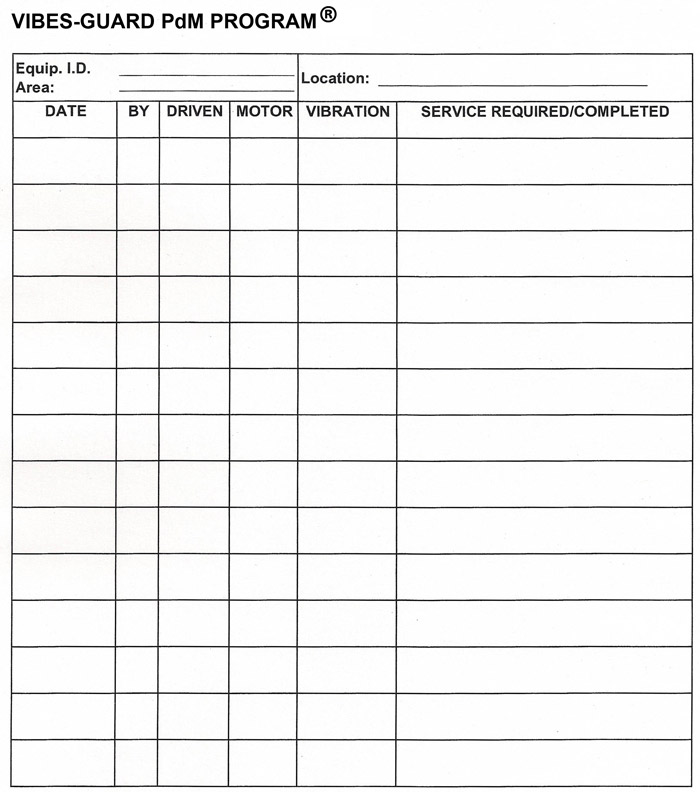

Consider VIBES-GUARD PdM Program® for all your critical machines on a regular schedule and start saving unnecessary breakdowns and costs in the future. We can also supply vibration protection products and monitoring systems.

If you have other questions pertaining to any particular machinery vibration or noise issues or require VIBES Corp services, sales, training, or free presentations, please email VIBES Corp (preferred) or call at any time: 604-619-9381 (24/7).

Yours in Serious Service,

Garrett Sandwell, MET, CVA, ASNT 3

CEO

© VIBES Corp 2004-2019

-1-LAV1.jpg?v=1)

-2-LAV1.jpg?v=1)

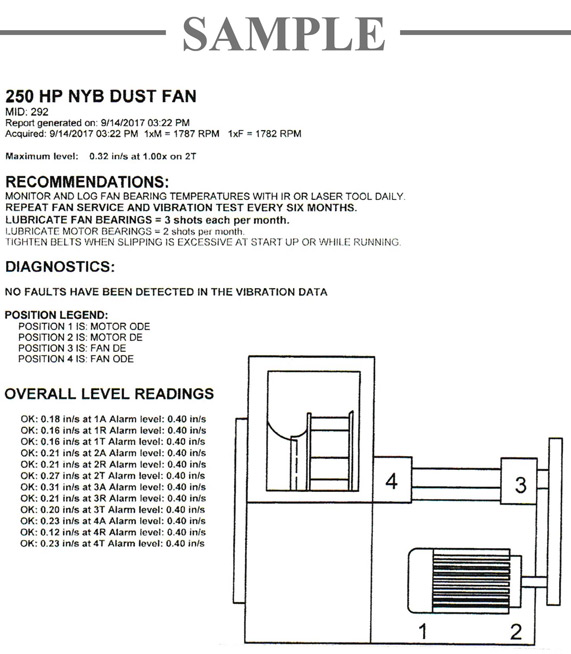

This is a machine health record card that can be installed near the equipment

Download the Vibration Severity Graph PDF to print or save it (or view the PDF in your browser)

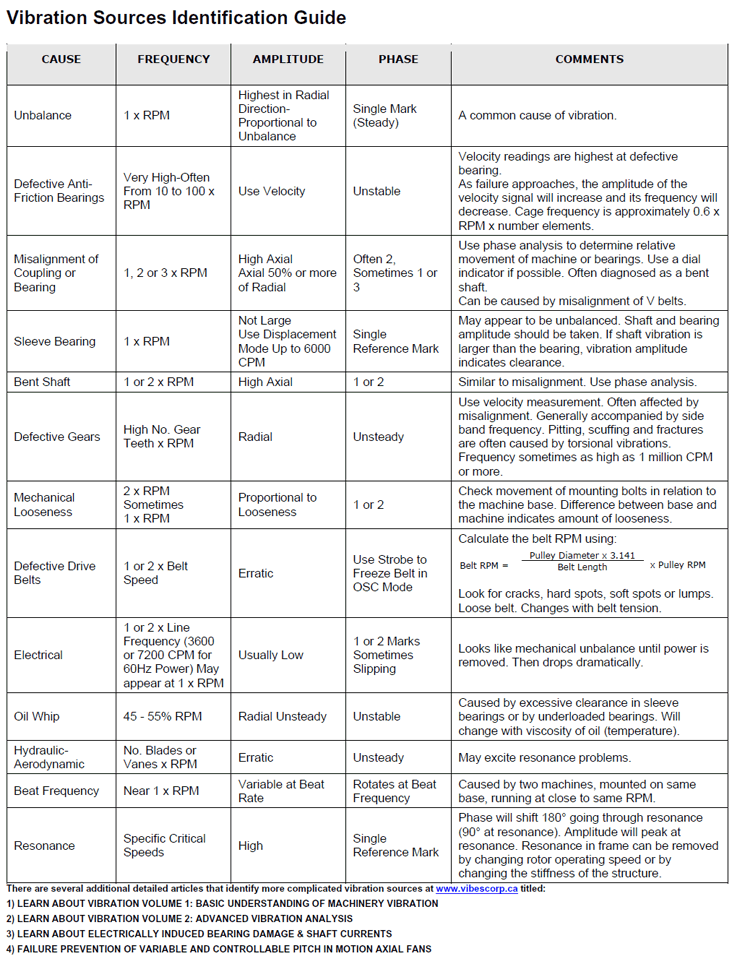

Download the Vibration Sources Identification Guide PDF to print or save it (or view the PDF in your browser)

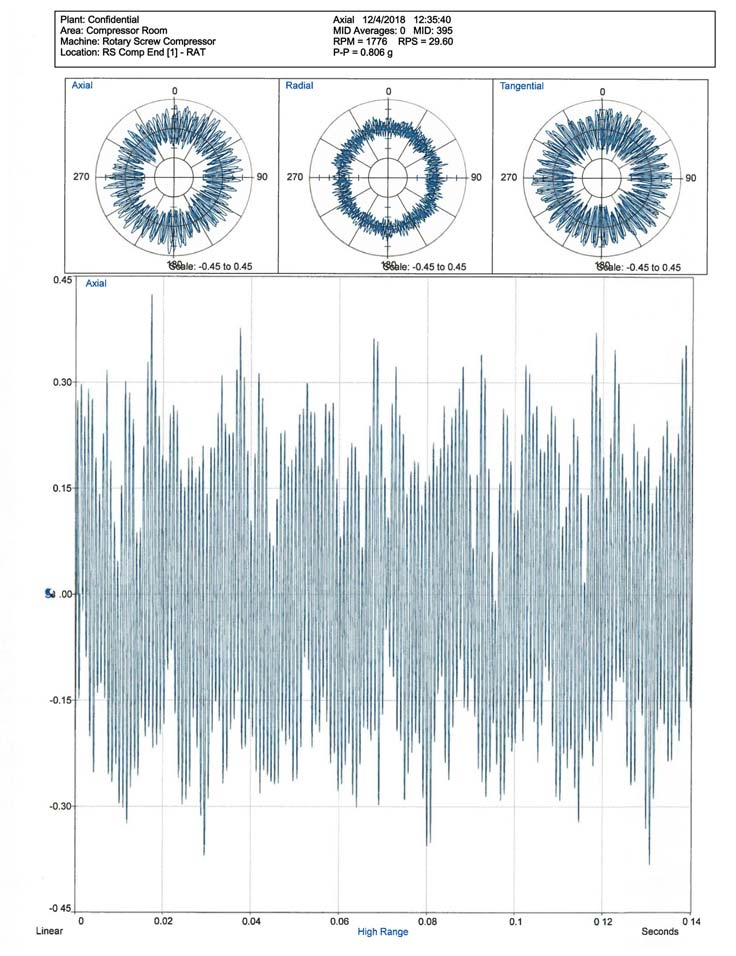

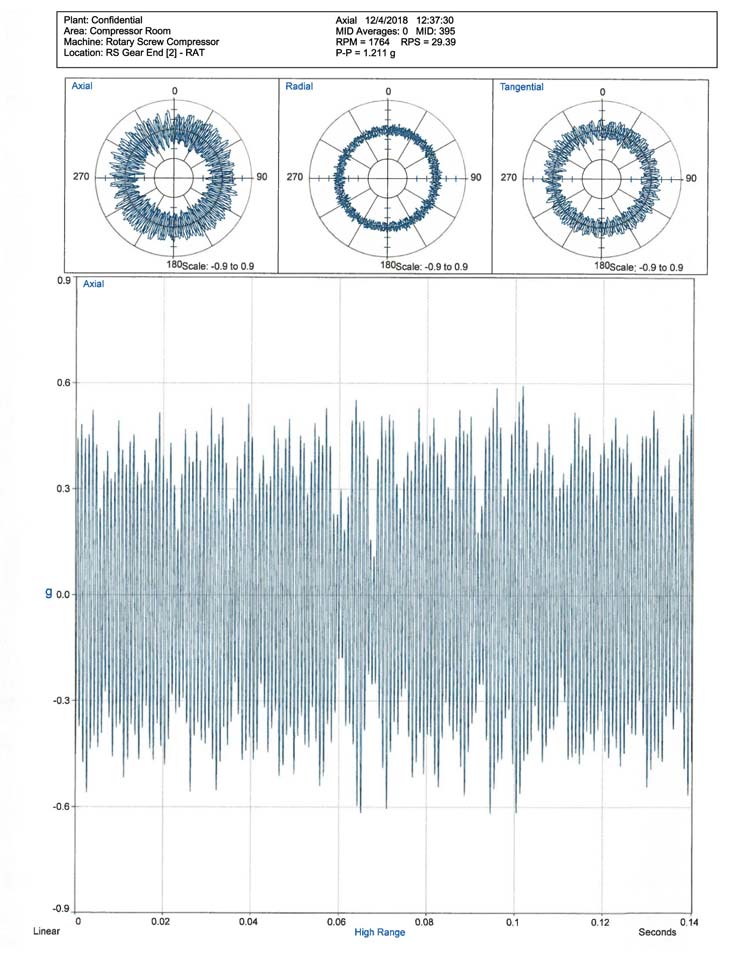

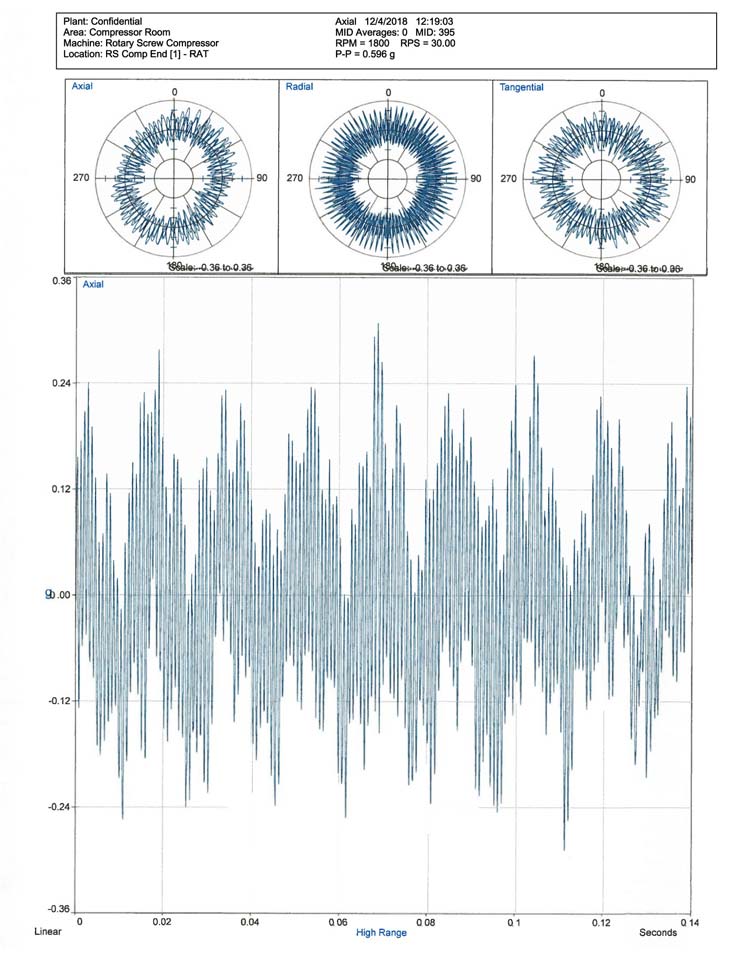

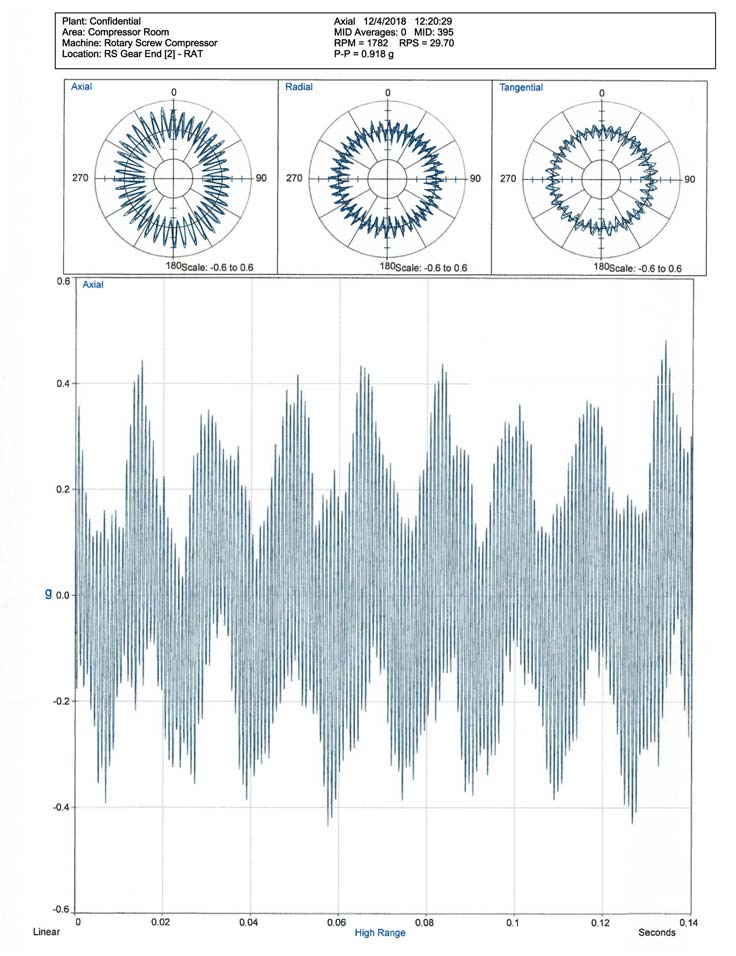

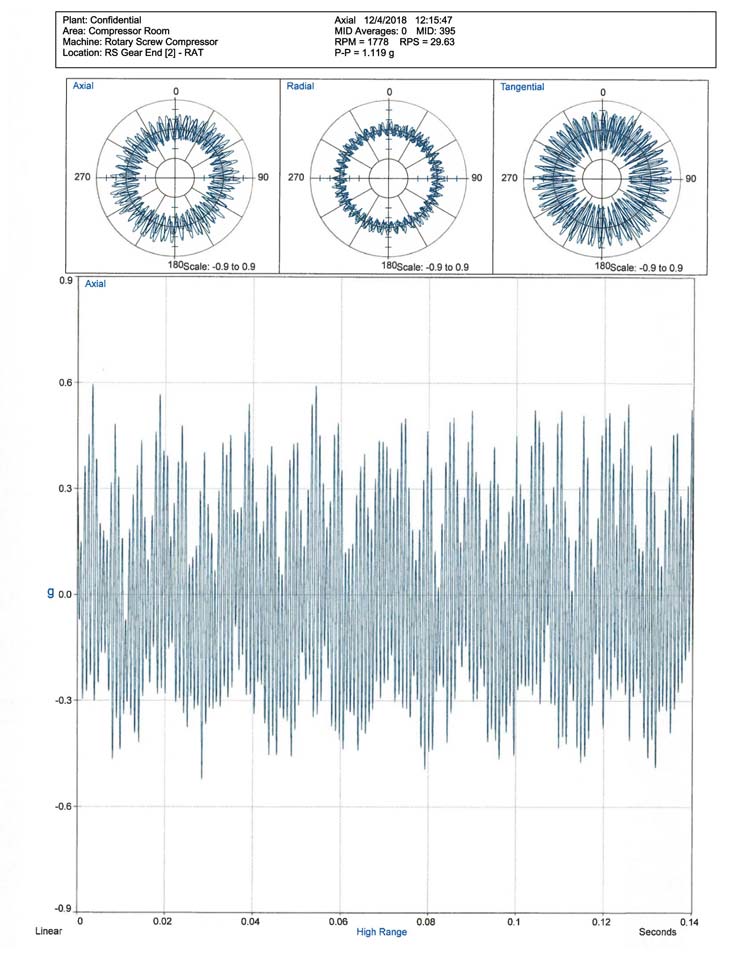

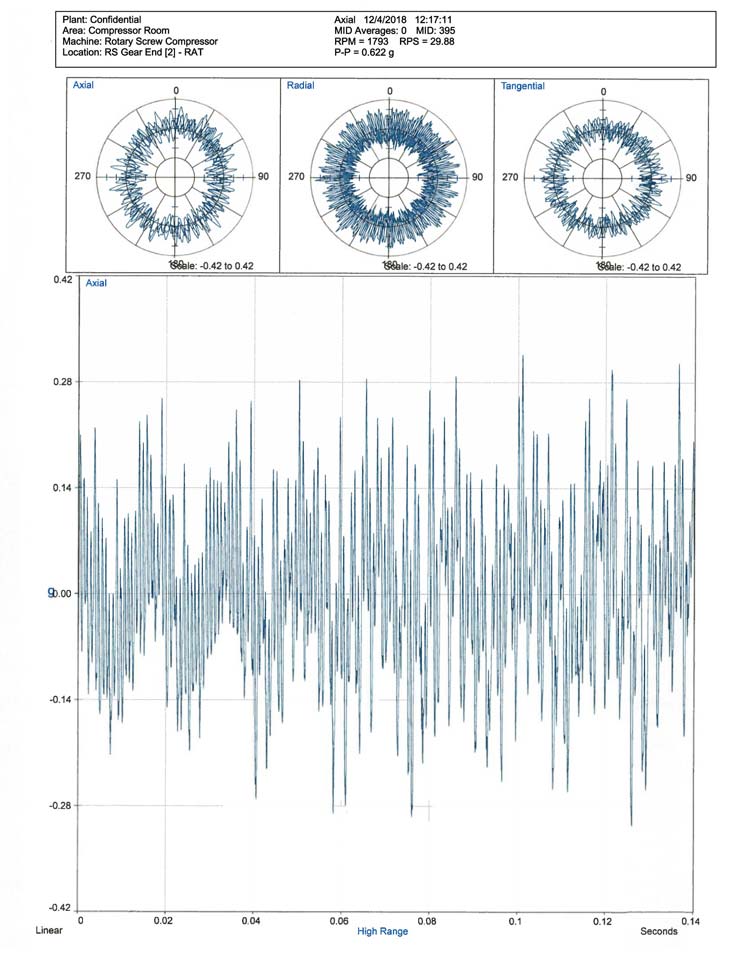

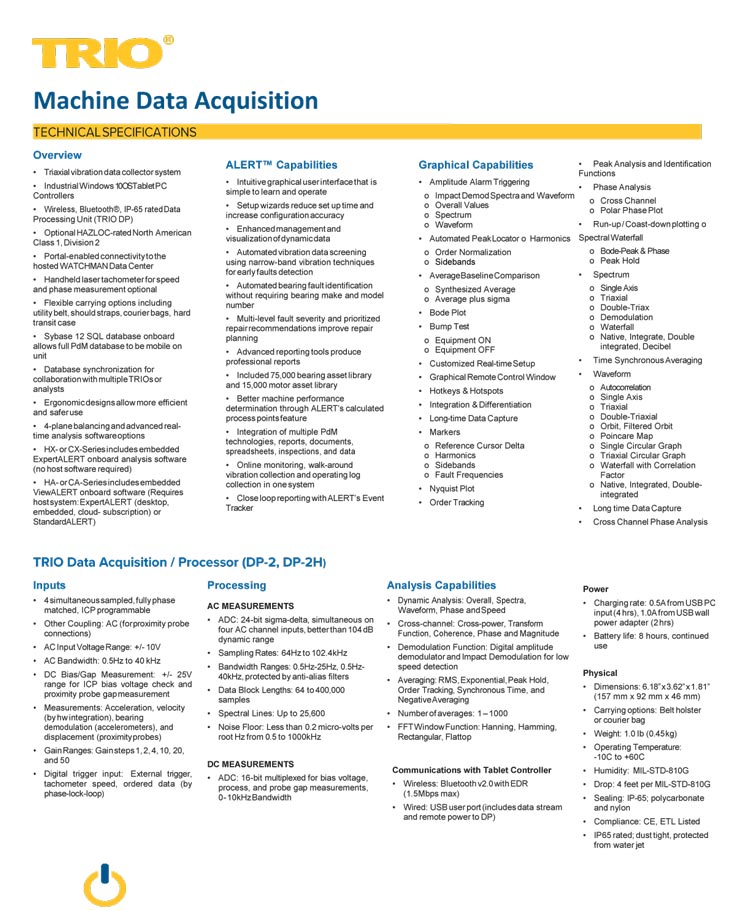

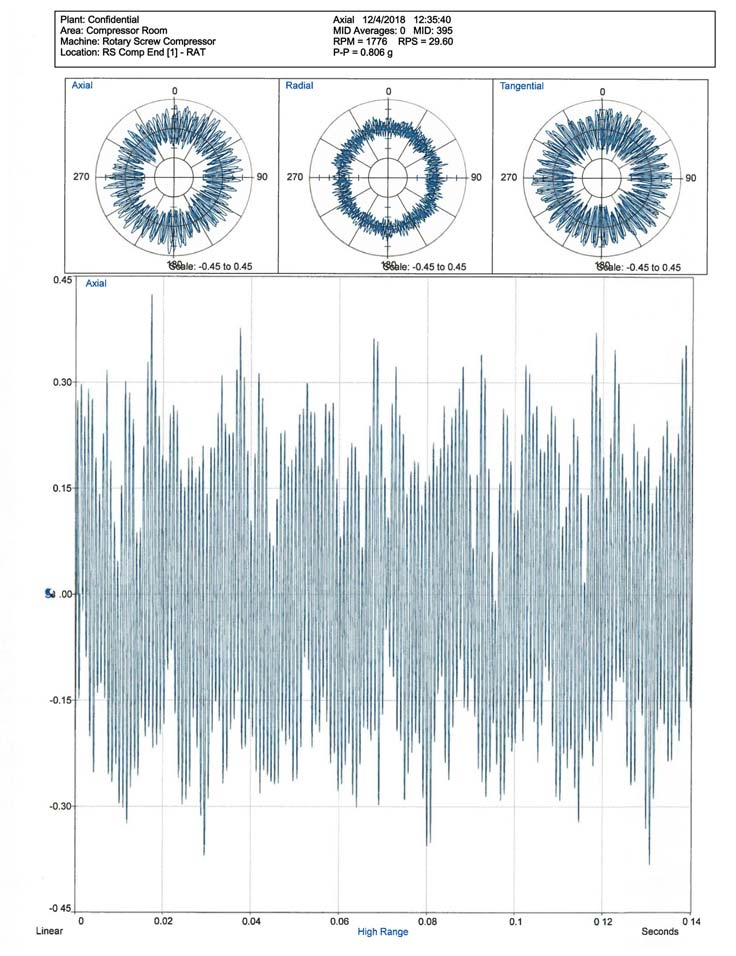

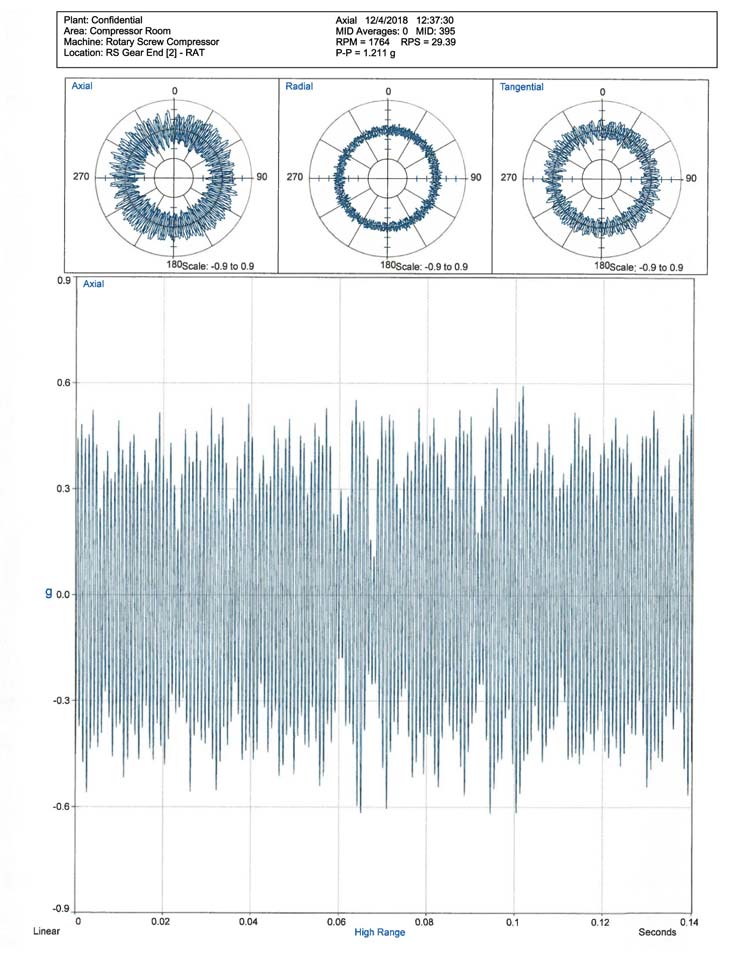

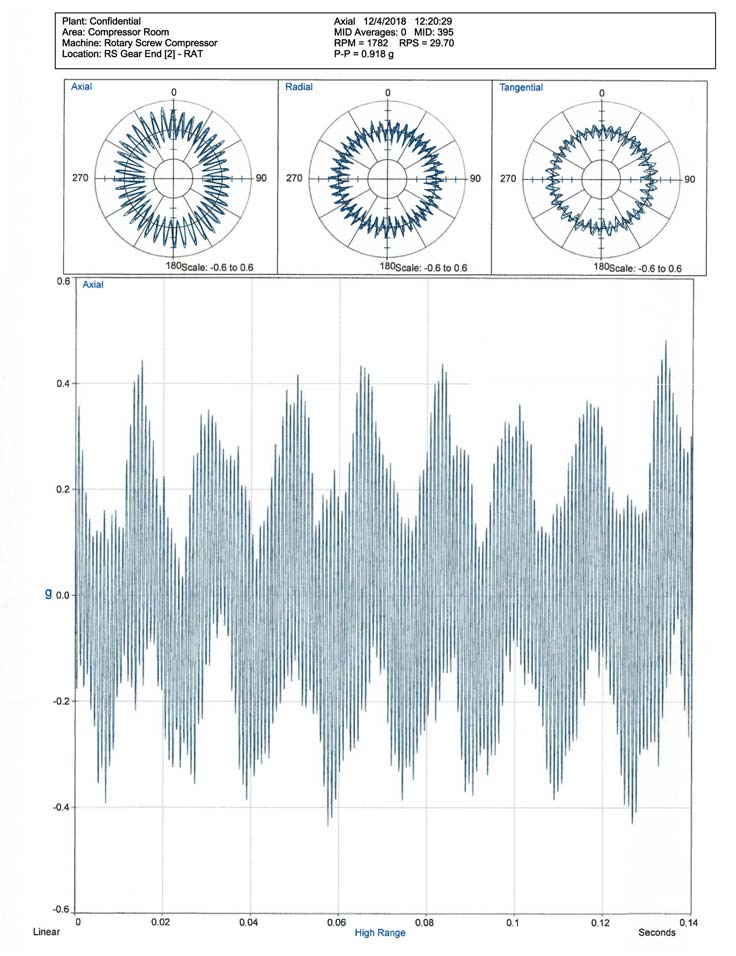

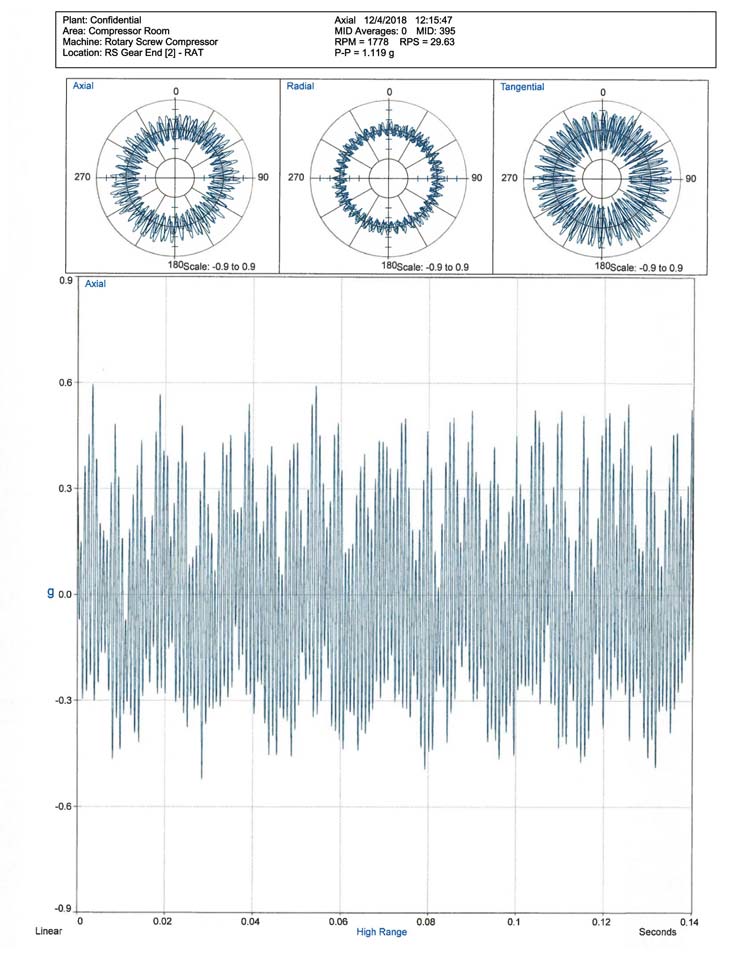

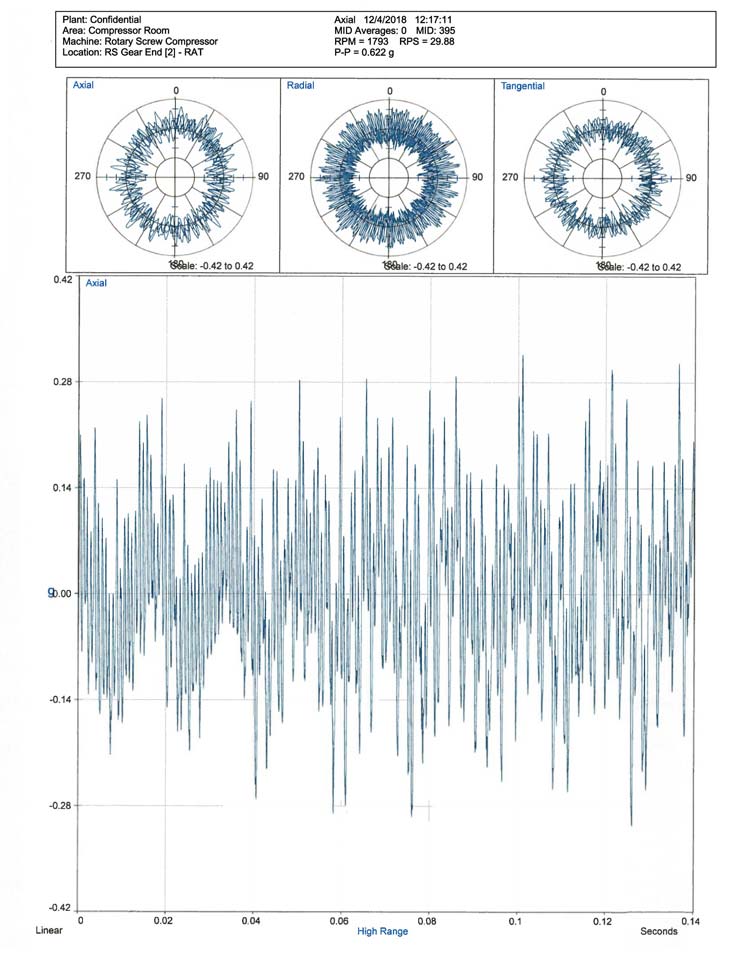

Vibration data recorded using AzimaDLI DCX RT - Software ExpertAlert 3.10 (2013-2016)

Vibration data recorded using AzimaDLI DCX RT - Software ExpertAlert 3.10 (2013-2016)

Vibration data recorded using AzimaDLI DCX RT - Software ExpertAlert 3.10 (2013-2016)

Vibration data recorded using AzimaDLI DCX RT - Software ExpertAlert 3.10 (2013-2016)

Vibration data recorded using AzimaDLI DCX RT - Software ExpertAlert 3.10 (2013-2016)

Vibration data recorded using AzimaDLI DCX RT - Software ExpertAlert 3.10 (2013-2016)

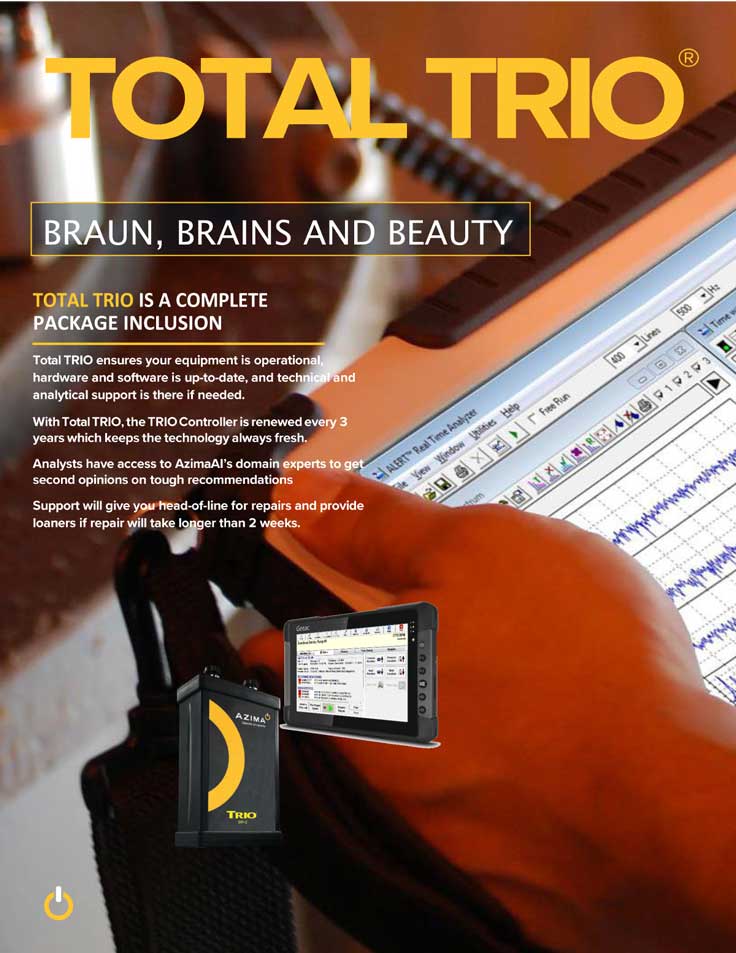

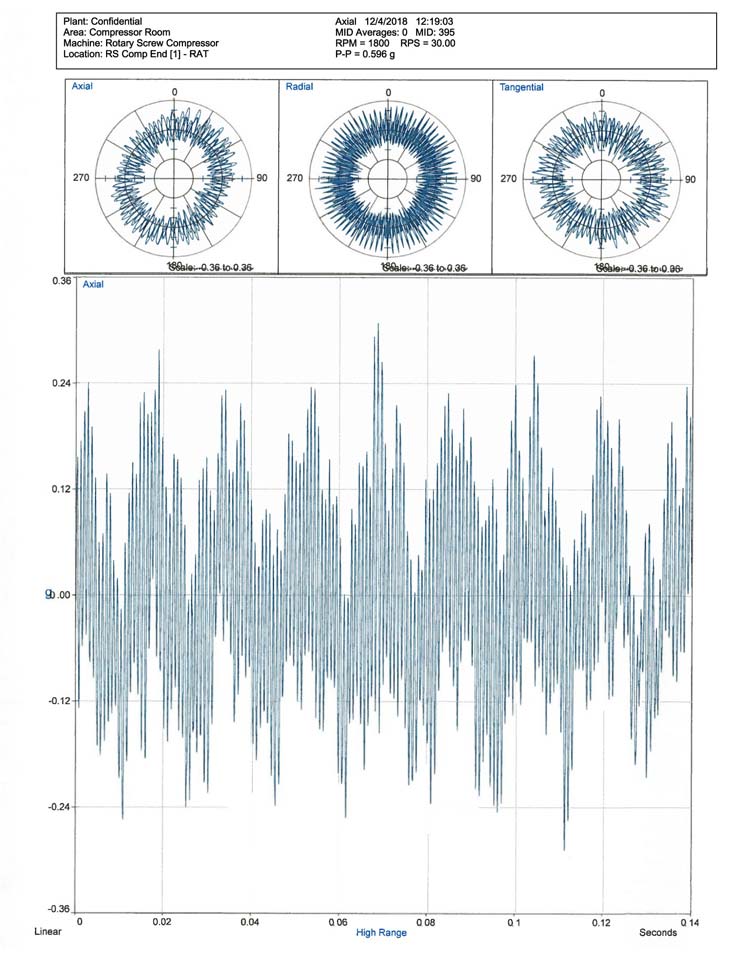

This is the equipment Vibes Corp has been using for 15 years with good results

Vibration data recorded using AzimaDLI CX 8 advanced data spectrum analyzer - Software ExpertAlert 4.0 (2019)

Vibration data recorded using AzimaDLI CX 8 advanced data spectrum analyzer - Software ExpertAlert 4.0 (2019)

Vibration data recorded using AzimaDLI CX 8 advanced data spectrum analyzer - Software ExpertAlert 4.0 (2019)

Vibration data recorded using AzimaDLI CX 8 advanced data spectrum analyzer - Software ExpertAlert 4.0 (2019)

Vibration data recorded using AzimaDLI CX 8 advanced data spectrum analyzer - Software ExpertAlert 4.0 (2019)

Vibration data recorded using AzimaDLI CX 8 advanced data spectrum analyzer - Software ExpertAlert 4.0 (2019)

Vibration data recorded using AzimaDLI CX 8 advanced data spectrum analyzer - Software ExpertAlert 4.0 (2019)

MACHINERY AND BEARING

FAULTS AND FAILURES

ROTATING MECHANICAL PARTS BREAKDOWNS CAN LEAD

TO VARIOUS PROBLEMS SUCH AS: PEOPLE SAFETY,

HVAC/R OR PRODUCTION SYSTEMS DOWNTIME AND

MAJOR COSTS.

MANY PROBLEMS CAN BE AVOIDED OR FOUND IN

ADVANCE IF A DEDICATED PREVENTATIVE MAINTENANCE

PROGRAM IS IMPLEMENTED INCLUDING:

- ACCURATE MECHANICAL INSPECTIONS AND

PREVENTATIVE MAINTENANCE

- BEARING NOISE AND ACCELERATION

- VIBRATION SPECTRUM ANALYSIS

- OIL SAMPLE ANALYSIS

- BEARING ACCELERATION, TEMPERATURE, NOISE

MEASUREMENTS AND TRENDING

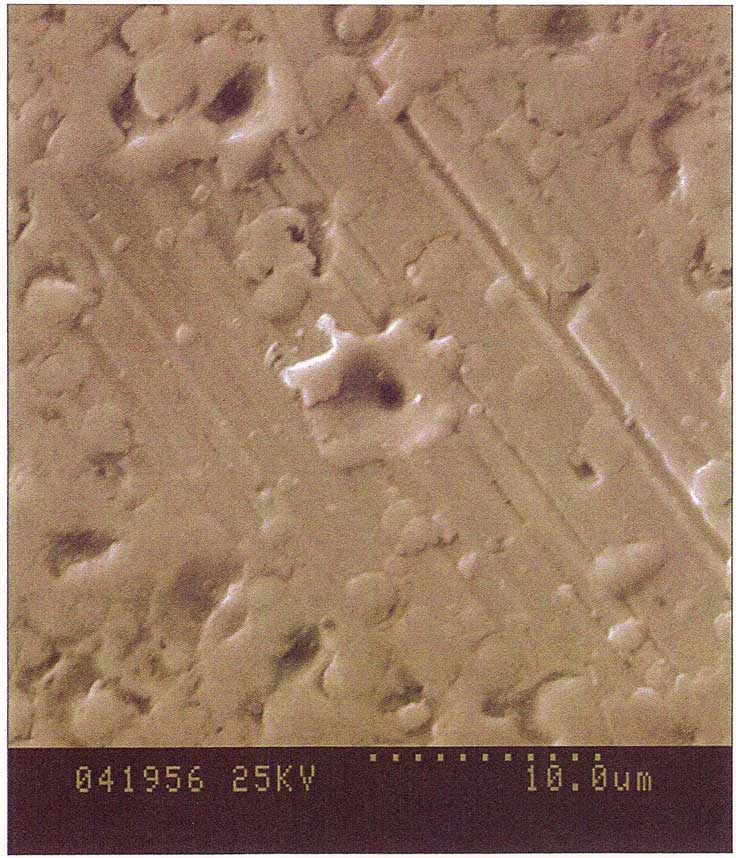

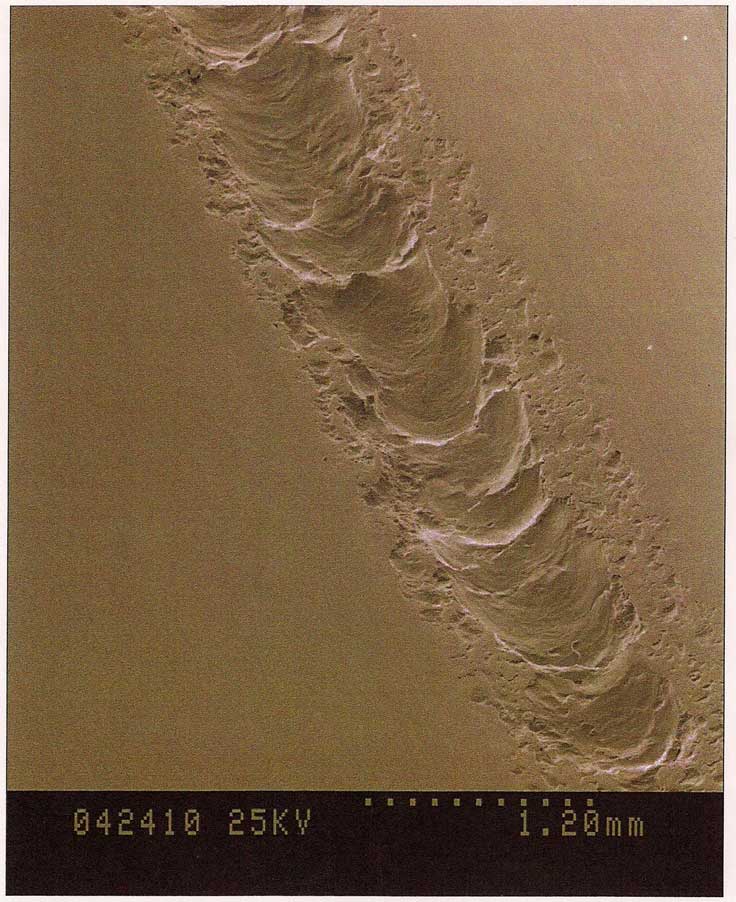

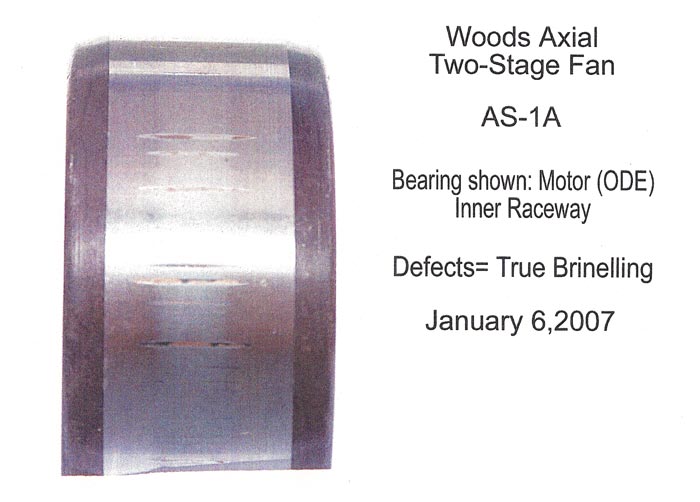

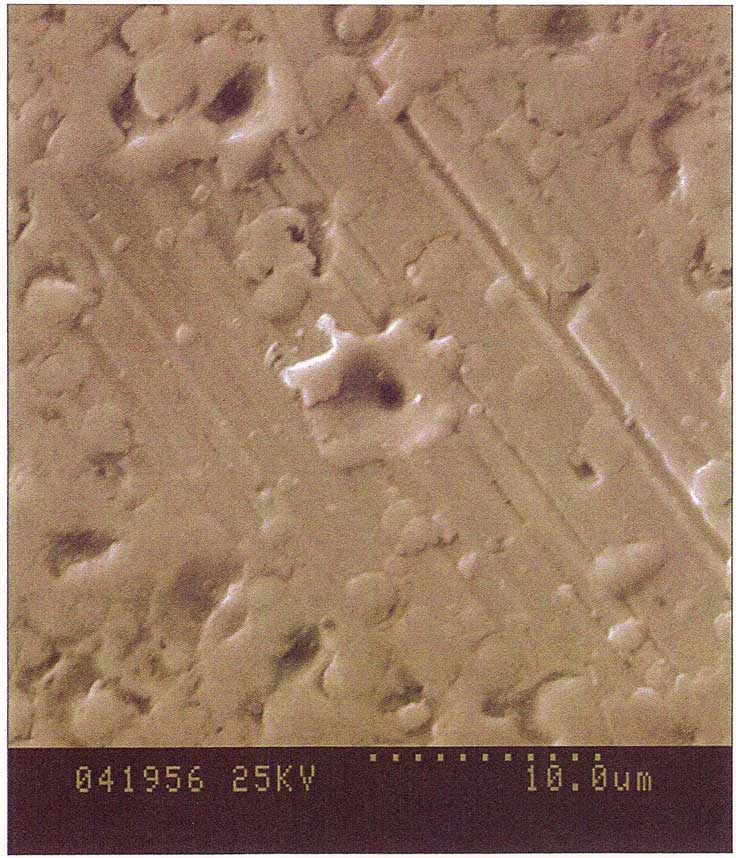

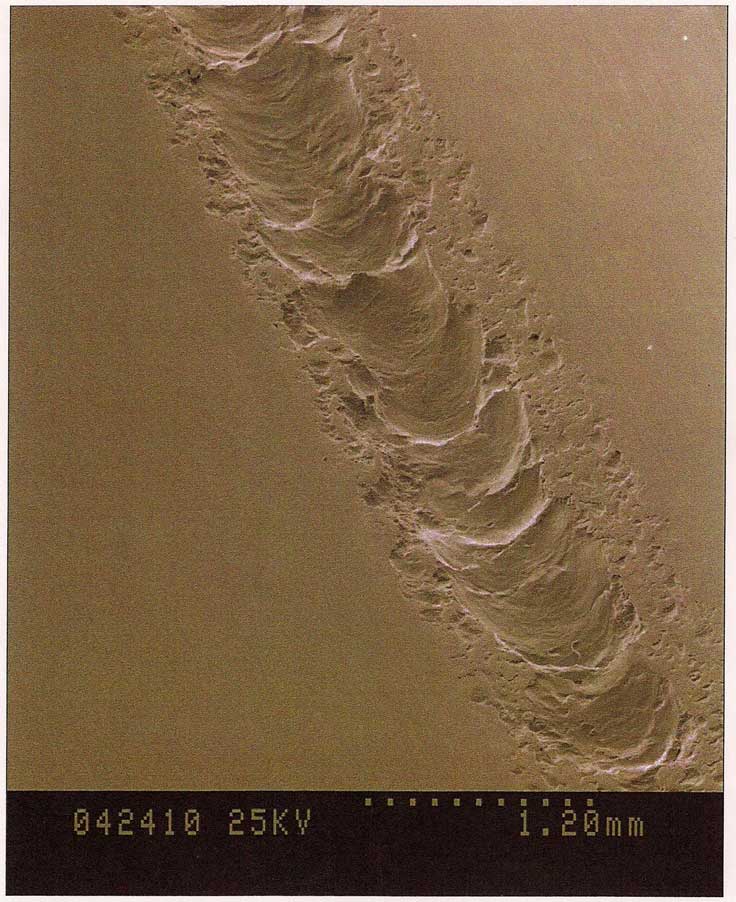

Electrically Induced Bearing Damage (EIBD) on a Bearing Race

The bearing race shown in this photo was found in the advanced stage of fluting.

EIBD/Shaft Currents is directly related to 460V (USA) and 600V (Canada) motor VFD applications.

A thorough EIBD article is available here.

Electrically Induced Bearing Damage (EIBD) on a Bearing Race

High magnification SEM view of particles flattened onto drive end outer raceway running surface showing variety of particle sizes. Material has clearly been molten at the time of deposit. Magnification 4,500X.

EIBD/Shaft Currents is directly related to 460V (USA) and 600V (Canada) motor VFD applications.

A thorough EIBD article is available here.

Electrically Induced Bearing Damage (EIBD) on a Bearing Race

SEM image of the spalling observed on the inside surface of the outer raceway. Magnification 37.5X.

EIBD/Shaft Currents is directly related to 460V (USA) and 600V (Canada) motor VFD applications.

A thorough EIBD article is available here.

For a more advanced understanding of machinery vibration, check out Learn About Vibration Volume 2: Advanced Vibration Analysis

Vibration & Electro-Mechanical Analysis, VIBES-GUARD PDM Program® Service Contracts, On Site - Rotors Dynamic Balancing & Custom Repairs,

Couplings, Pulleys & Drive Shafts Laser Alignment, Rogowski Coil (VFD) Electrical Discharge Tests & Reports.

Sales: WEG Electric Motors, Metalon Synthetic Grease, Cool Blue (Inductive Absorbers), Easy Laser, Wilcoxon / Endaq Vibration & Temperature Monitoring & Protection Products, (Misc) Isolation Springs, Drive Parts & Bearings, Machining, Fabrications, Sheet Metal Projects & Environmental Coatings. Learn About = Free Articles.

|

-1-LAV1.jpg?v=1)

-2-LAV1.jpg?v=1)